It has been well accepted and established that forage producers should analyze forages to determine nutrient levels and ultimately the quality of the feed. However, there has been a lot of confusion about whether forages should be analyzed by wet chemistry methods or near infrared reflectance spectroscopy (NIRS).

Many nutritionists are quick to brush off NIRS, citing poor accuracy of the method. However, NIRS has come a long way from its introduction to forage analysis. The instrumentation has improved, and the NIRS Forage & Feed Testing Consortium (NIRSC) has made great strides to standardize and optimize the use of NIRS across the industry.

NIRS is a method of analysis using the same principles as many wet chemistry methods. Wet chemistry methods of analysis use a standard curve to compare an unknown sample to known concentrations to determine nutritional values. NIRS uses spectra generated by a detector measuring the reflectance of near infrared light on a sample.

A library of sample spectra with known constituents (for example, percent protein and percent acid detergent fiber [ADF]) determined by industry standard wet chemistry methods is compared with the spectra of an unknown sample. Based on how the unknown sample’s spectra compares with those in the known library, nutritional values can be determined.

So, why use NIRS when wet chemistry methods could be used instead?

There are several benefits of using NIRS. First, with no chemical inputs, technician time is the only true cost to a NIRS analysis. In just one NIRS scan, multiple constituents can be measured from one larger test portion versus setting up multiple wet chemistry analysis using multiple test portions. Therefore, NIRS is a low-cost analysis ($15 to $20 instead of $30 to $40 for fewer constituents).

Second, the samples just need to be dried and ground. There are no extractions necessary, so with little sample preparation it is a rapid turnaround analysis. Third, the method is nondestructive. This allows researchers to preserve their sample and producers to request more wet chemistry analysis, such as minerals or nitrates. Fourth, because no chemicals are required for analysis, there is no hazardous waste produced, eliminating waste management issues and making NIRS an environmentally friendly solution.

Finally, because the technician simply loads the cup to be scanned on the instrument, there are fewer sources of potential human error. A report produced with equations from the NIRSC, which has 15 constituents, would require 179 technician handling events for wet chemistry. That’s 179 points where human error could occur versus one for NIRS!

Proven repeatability

The NIRSC has complied data to show that NIRS methods improve repeatability and reproducibility over wet chemistry methods. Seven NIRSC member labs shared their data from 33 alfalfa hay samples that were analyzed from 2013 through 2019 as participation in the proficiency testing conducted by the National Forage Testing Association (NFTA).

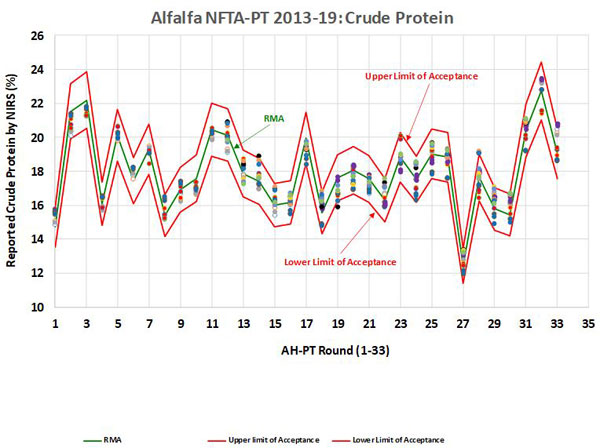

Figure 1 shows crude protein results in comparison to the reference method average (RMA). The reference method for protein is wet chemistry analysis of nitrogen by the Kjeldahl method. The RMA is the average result reported from all labs using the specified method. Upper and lower limits of acceptance are assigned by NFTA for each round of proficiency testing.

Almost all of the crude protein results reported by the NIRS labs are within the acceptance windows assigned by NFTA based on the wet chemistry method. Therefore, this is a robust demonstration that NIRS is as accurate as wet chemistry. We would like to point out that the NIRS calibrations must be based on precise, accurate, and robust wet chemistry for this outcome.

The Horwitz ratio is an index used to measure the precision of a method across laboratories (reproducibility). Lower ratios indicate better reproducibility. When applied to lab testing results, the NIRS Horwitz Ratios are overall lower than with wet chemistry, demonstrating that reproducibility of NIRS is better than wet chemistry despite NIRS technique being based on wet chemistry data. We conclude that NIRS calibration models developed using good science and applied properly, maintain better interlaboratory precision than wet chemistry methods.

Better hardware

Instrumentation for NIRS analysis has improved through the years. New technology has led to better prediction. Currently, there is less variation from instrument to instrument than there previously had been, according to David McIntosh of the NIRSC Instrument Hub located at the University of Tennessee in Knoxville. In addition to instrument upgrades, the formation of the NIRSC has led to standardized use of NIRS technology to analyze forages across the industry.

The NIRSC has created guidelines for laboratory sample preparation. This means across member labs, subsampling, drying, and grinding of samples is consistent. Improved consistency of samples being scanned on the instrument improves the reliability of analysis. The group also provides support to member labs, ensuring accurate sample results.

In conclusion, NIRS analysis of forages is an acceptable way to determine nutritional values and forage quality. It has the advantages of being affordable, rapid, non-destructive, repeatable, and environmentally friendly. The instrumentation for NIRS analysis has improved through the years and is reflected by accurate predictions.