It’s on the tag and in the bag |

| By Robin Newell |

|

|

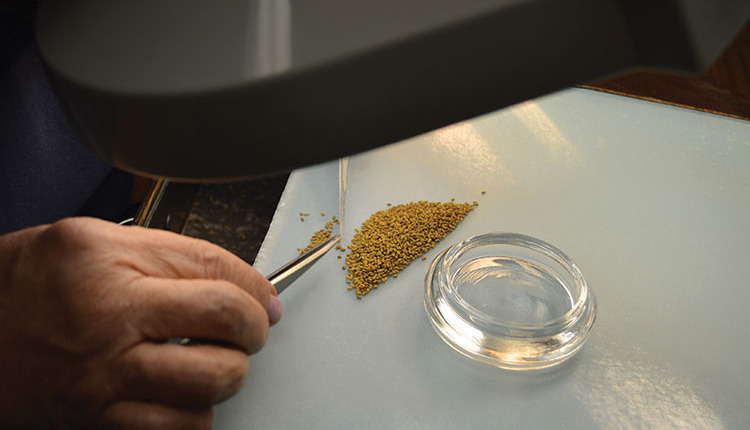

The author is the vice president of North American sales for S&W Seed Company.  A registered seed technologist performs a purity analysis on a clean sample of seed. Danette Kroft In prior Hay & Forage Grower articles, we covered alfalfa variety breeding and characterization, the progression from breeder seed through foundation to commercial seed, and some basics of alfalfa seed growing and cleaning. Now let’s wrap up this series with seed purity analysis, treatment and packaging operations, and labeling requirements for commercial sale and planting.  Total germination shown on an alfalfa seed tag includes normally germinated seedlings plus hard seed. Abnormal seedlings and dead seed are not included in total germination. Danette Kroft Total germination as shown on an alfalfa seed label or tag is the sum of hard seed plus normal germinated seedlings. Normal seedlings have healthy tissue with a normal hypocotyl and cotyledons. Hard seed is not swelled even after seven days. Unlike hard seed, dead seeds squash easily under gentle pressure. Abnormal seedlings have a missing root or deformed hypocotyl. Dead seed and abnormal seedlings are not included in total germination. For seed purity analysis, a registered seed technologist performs a visual analysis under magnification, separating and weighing any material in the sample that is not alfalfa seed. Required categories on the seed label include pure seed, other crop seed, weed seed, and inert material (may include inert coating material). Pure seed is just that . . . pure seed with no coating material. Other crop seed is self-explanatory.  Scarification may be used prior to alfalfa seed treatment and packaging. This mechanical scarifier has rotating leather paddles that rub seed against the inside surface of a screen to reduce hard seed content. Checked for weeds Weed seeds in the sample must be individually reviewed and identified as noxious or non-noxious. Noxious weed species are designated by state statutes and can vary by state. If any noxious weed seeds are present, they must be further identified as prohibited (cannot offer for sale) or restricted (must be below a threshold to offer for sale, often requires listing on the label to show the weed species and number of weed seeds present per pound of seed in the bag). Inert material is everything else, including tiny rocks, dirt, and pod or stem pieces. Coating material is usually listed separately from inert material. If the variety is Roundup Ready, a sample is tested to ensure the trait provider’s minimum required trait purity of 90 percent. The three major seed suppliers cooperate to monitor low level presence of the Roundup Ready trait in conventional seed lots, testing all their conventional alfalfa with lateral flow protein strips to detect low level presence. Field lots that are “nondetect” can be chosen for more rigorous testing with PCR (polymerase chain reaction) if needed for seed export, or to provide seed for growing “nondetect” hay for various end-use markets. Seed of each individual field lot remains stored in the seed plant until the seedsman decides to use it for commercial packaging. Individual field lots of the same variety are often blended together for efficient field lot utilization or to attain a larger finished lot size. Seed may be scarified to reduce hard seed content, scratching the impermeable seed coat of hard seed just enough to permit soil moisture absorption. Seed treatments added The next step is treatment. Fungicide treatment and rhizobium inoculant application are standard for most alfalfa seed. Any seed treated with a fungicide must also receive colorant that is visually different from natural seed color. Other treatment materials can run the gamut from micronutrients to microbials. The treatment stage is also when inert coatings can be applied. A growing proportion of alfalfa seed in the U.S. is sold with various amounts of inert coatings ranging up to one-third of the product’s total weight. As inert coating percentage goes up, pure seed shown on the seed label goes down. Finished seed is packaged according to weight. Whether bagged or in bulk, a seed label must be affixed to commercial seed packaging to comply with the Federal Seed Act and must furthermore comply with requirements of individual states where the seed package will be offered for sale. Most states allow agricultural seed to be sold within nine months following the germination test date; after that time period, a new germination test is required and revised labeling is attached for continuing sales. Some states allow a longer period, and the number of months varies by state.  On the packaging line, alfalfa seed is weighed and seed bags filled within an enclosed box. Filled seed bags move to the left on a conveyor to receive a label, sew tape to prevent seed leakage, and then get sewn across the top. This packaging process requires about 24 seconds per bag. Check your label State inspectors are authorized to check commercial seed for compliance to seed labeling laws and may pull random samples for analysis to ensure labeling compliance within tolerances outlined in the Federal Seed Act. An inspector can place a “stop sale” order on seed that is out of compliance. Commercial alfalfa seed cannot be certified with blue certification labels unless the breeder submits characterization data and obtains approval for variety recognition through the National Alfalfa Variety Review Board authorized by the Association of Official Seed Certifying Agencies. The majority of alfalfa seed sold in the U.S. is not certified with blue labels, thus seed buyers are trusting their seed supplier to provide seed of the variety stated on the seed label. The Federal Seed Act requires that a variety once sold under a specific variety name must always be sold with that variety name, except when labeled as “Variety Not Stated.” The use of a brand name in lieu of an approved variety name for promoting seed is generally permissible. When seed is labeled as an individually branded product, the seed label must also show the true variety name or may show “Variety Not Stated” where permissible under state seed statutes. The next time you fill your seeder with alfalfa seed, take a look at the label to understand more about the purity and quality of the seed you’re planting. This article appeared in the April 2017 issue of Hay & Forage Grower on pages 26 and 27. Not a subscriber? Click to get the print magazine. |