Beef baleage |

| By Lauren Peterson |

|

|

|

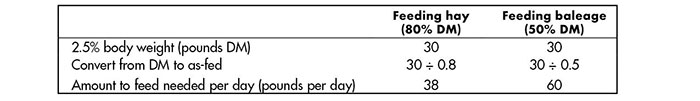

Baleage is ensiled at 40 to 60 percent moisture, while dry hay commonly is stored below 20 percent moisture and silage above 65 percent, explains Kim Mullenix, beef cattle systems extension specialist with Auburn University in its Timely Information animal sciences series. Its use is becoming more widespread as producers strive for higher quality forage and cut down wilting time. It is important to know each herd’s nutrient requirements before deciding to feed baleage as it could provide an opportunity to reduce other supplemental feeds. Mullenix provides an example of research showing that annual ryegrass harvested as baleage at boot stage ranged from 60 to 65 percent total digestible nutrients (TDN) with 10 to 16 percent crude protein (CP). Ideal for cow-calf operations, Mullenix recommends forage testing to ensure that the herd’s daily nutrient requirements are being met and provide additional supplementation if needed. Quality and quantity “The stage of plant maturity at harvest is the single largest factor affecting the feeding value of baleage. The nutritional quality of baleage will only be as good as the starting product,” Mullenix says. Though harvest timing is important, the storage process has just as much impact on quality. Mullenix notes that bales with moistures between 40 and 60 percent require at least six layers of plastic to provide a stable product and minimize storage losses. The amount of feed cattle consume on a dry matter basis is important to consider in order to develop a nutrition plan. Factors such as animal weight, stage of production, forage quality, and the environment all affect dry matter intake. Mullenix notes that the average mature cow will consume about 2.5 percent of its weight in dry matter (DM) per day. Because of this, if producers plan on using baleage, more baleage by weight will be needed to satisfy the same group of animals than if dry hay is fed, she adds. The following example shows how much feed is required for a 1,200-pound brood cow in both scenarios.  Additives and spoilage There are a number of inoculant products on the market to help preserve high-moisture feeds. “They do not add additional pounds of total digestible nutrients or crude protein, and cannot be used to mask the effects of harvesting over-mature forage. Additives mainly work to rapidly drop the pH within the bale, which promotes fermentation and preservation of the dry matter and nutrients present,” Mullenix says. Throughout the fermentation process, potentially life-threatening bacteria such as Listeria monocytogenes and Clostridium botulinum can thrive in the warm, moist environment. Mullenix warns that spoilage can occur due to high moisture (over 65 percent), soil or manure contamination, improper sealing, and high pH. Warning signs include dark black or brown bales, wet or slimy feed, a rancid smell, and animals refusing to eat. Mullenix recommends calling a veterinarian immediately if cattle appear disorientated or continuously salivate, as these can be signs of an impaired nervous system or brain inflammation caused by botulism. “Some mold on the surface of bales is often seen,” Mullenix notes. “Tightly wrapping bales will help decrease the amount of mold occurrence.” Feeding enough baleage to ensure the feed is completely consumed within two days, or one in the summer months, can minimize bale spoilage. Feeding in cone- or ring-type feeders, cradles, or on trailers helps reduce wastage. Baleage can also be chopped to use in mixed rations. Mullenix reminds producers that starting young or growing cattle on a baleage diet will require an adjustment period, as with any other new ration.  Lauren Peterson Lauren Peterson served as the 2017 Hay & Forage Grower summer editorial intern. She is from Wyanet, Ill., and currently attends Kansas State University where she is pursuing a degree in agricultural communications and journalism. While at school, Lauren works at the KSU dairy farm and is an active member of the Horseman’s Association. |