Three keys to mitigating feed hygiene challenges |

|

|

|

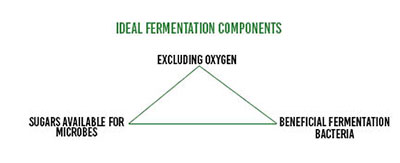

This item has been supplied by a forage marketer and has not been edited, verified or endorsed by Hay & Forage Grower.  “We see water-logged fields that have serious potential for high ash content,” explains Dr. John Goeser, animal nutrition, research and innovation director for Rock River Laboratory. “Those preparing their hay with additionally required merging, raking, and tedding due to wet conditions may be unknowingly helping this potential come to life.” Goeser explains that wet fields carry a number of opportunities for ash (soil contamination). “Tires pick up mud, tines hit the ground kick up mud or soil, and rainfall has already potentially splashed added soil up onto standing plants.” Not to mention that flooding seen across the US leaves silt and soil on standing plants – if they haven’t died. “All of this additional cellular rainwater can further activate and potentially carry bad bacteria, mold, and yeast into and around forage,” explains Goeser. “Rain drives fungi from the soil and ash onto standing or cut plants and these microorganisms are then better able to grow in these types of moist environments.” Optimal fermentation is the trump card Despite all of the vectors for disaster to arise, there are ways to mitigate the risks involved with these feed-hygiene challenges. “Harvesting the crop at the right moisture is going to be all that more critical,” says Goeser. “But, if farmers are forced to decide between the right moisture and the forage getting rained on post-cutting, I recommend chopping it wetter to avoid a rain event, this year.” Rain on forages prolongs drying, leading to low sugars in the plant, and requires more management like raking and tedding that tends to increase ash contamination. By avoiding rain, forage has a better chance of fermenting to some extent, to mitigate any hygienic caveats. “The right bacteria and sugar present, plus correct packing, is highly important to fermentation,” stresses Goeser. “Pour a research-backed inoculant on it at potentially greater rates than typical, separate it from other forages, avoid blending it with past year forages, utilize good fermentation management practices, and feed it sooner than later. But what are good fermentation management practices? Ideal fermentations require a few key ingredients: exclusion of oxygen, a beneficial fermentation bacteria population present (for example, inoculant), and available sugars for the microbes to work (Figure 1). “If any of these factors are compromised or forage has been heavily rained on, over a quarter of an inch, the use of acid products can be an alternative for those ingredients” states Goeser. Figure 1: Ideal Fermentation Balancing for quality Forage quality is key every year, but especially in years when forage inventories may come up short. “Harvesting forage at the highest quality possible, considering the conditions, is really important,” explains Goeser. “And if the first crop fell short, try to hit the best second, third and fourth cuts to make up the quality.” To assess quality, Goeser recommends walking fields, utilizing a PEAQ stick with the first cut, scissor clippings with later cuts, and managers that can help. “Pull together your consultant team and get them talking to discuss the current status and optimizing quality – that includes your nutritionist and agronomist.” Despite these recommendations, many can attest that forage harvest and planting has been tricky in 2019. “I know we’re eager to get in the fields to get hay off so we can plant corn,” says Goeser. “But we don’t want to destroy the soil structure within the fields - especially with the winter kill - unless we’re taking off alfalfa to plant corn.” Commodity protection While current forages are the priority when it comes to preventing or mitigating the challenges from anti-nutritional factors, on-farm commodities are also susceptible to these same risks. “Commodities in bays have been flooded with rain, which can wreak havoc on their quality,” explains Goeser. He recommends cleaning commodity facilities out completely between low supplies and new shipments, as opposed to dumping in front of the old, contaminated commodities. He also stresses, “proactively ensure the next delivery isn’t contaminated to start on the right foot.” 2019 may be an extension of last year’s forage woes albeit in a slightly different fashion; yet producers are better equipped and informed to proceed proactively. Knowing what factors begin a chain of events that lead to poor quality or contaminated forages can be the best means to outline a plan to negate those challenges. As Goeser recommends, “assess quality, discuss with your consultant team, and work toward an optimal fermentation to avoid fermentation and feed cleanliness issues in 2019.” About Rock River Laboratory Founded in 1976, Rock River Laboratory is a family-owned laboratory network that provides production assistance to the agricultural industry through the use of advanced diagnostic systems, progressive techniques, and research-supported analyses. Employing a team of top specialists in their respective fields, Rock River Laboratory provides accurate, cost-effective, and timely analytical results to customers worldwide, while featuring unsurpassed customer service. |