Soil moisture sensing for forage irrigation |

| By Matt Yost, Jonathan Holt |

|

|

|

Yost is an agroclimate extension specialist at Utah State University. Holt is a graduate research assistant.  According to the most recent irrigation survey conducted as a part of USDA’s agricultural census in 2017, visually examining the crop was the most commonly used irrigation method by irrigators in the western United States. One large concern with this practice is that yield potential can already be lowered once the visual signs appear. Exploration of the different tools available and selecting the ones that work well with individual management plans can help growers ensure that irrigation is scheduled precisely. One tool that is becoming more commonly used is soil moisture sensors because of their ability to constantly monitor what is happening in the soil. Selecting a soil moisture monitoring system can be a daunting task given the diversity of options, applications, and the range in costs. There are four basic steps for selecting a sensing system. They are:

Potential or volume?  water potential — gypsum block sensor. Soil moisture sensors either measure water potential or a volumetric water content. Water potential is the amount of force exerted by the plant roots to get water out of the soil. As the soil dries out, the water potential decreases, and the plant has to exert more force to extract water from the soil. Water potential sensors are essentially a resistor in a gypsum block, or a resistor inside a granular matrix with a stainless steel enclosure around it (see photo). As the resistance in the sensor changes due to variations in soil moisture, the data logger converts the ohm measurements into water tension or water potential scales that can be used to determine if irrigation is necessary. Volumetric water content is the ratio of the volume of water compared to the entire volume of the soil, and it is reported as a percent. In ideal soil, about 50% of the volume would be solids and the other half would be pore spaces that act as reservoirs for water and air. Depending on the soil structure, the volumetric water content at field capacity (maximum amount of water the soil can hold) can be anywhere from 15% to 44%. On the other end of the scale is the permanent wilting point, where the plant can no longer pull water from the soil, and that varies from 8% to 23% depending on the soil structure. Two of the most common types of water content sensors include time domain reflectometry (TDR) and frequency domain reflectometry (FDR) sensors. TDR sensors offer a high level of accuracy, as they are not affected by salt, temperature, and only minimally by ground compaction. The most common TDR sensors have two or three metal prongs attached to a small plastic body (see photo).  Water Content — time domain reflectometry (TDR) sensor. We are not aware of any single sensor that can measure both water potential and water content, but both metrics are useful for guiding irrigation. Water potential is better suited for timing when to irrigate, while soil water content is better suited for adjusting how much irrigation to apply. Thus, a combination of both types of sensors might be ideal for adjusting timing and rate of irrigations. Needed components There are four basic components of nearly all soil sensing systems:

Soil sensors are the essential part of any soil monitoring system. The other components are not always required. They depend on the manufacturer offerings and the customer’s preference. Each type of sensor system has its own specifications such as the number of sensors a single logger can support or data access fees. If you are not willing to visit the soil sensors to manually collect the data each time it is needed, telemetry that enable remote access on a phone or computer may be well worth the investment. The worst mistake you can make with soil moisture sensing is to purchase equipment and never use it to modify your irrigation. How many systems? This is an extremely important question that often needs to be answered on a field to field basis. The two keys to consider include:

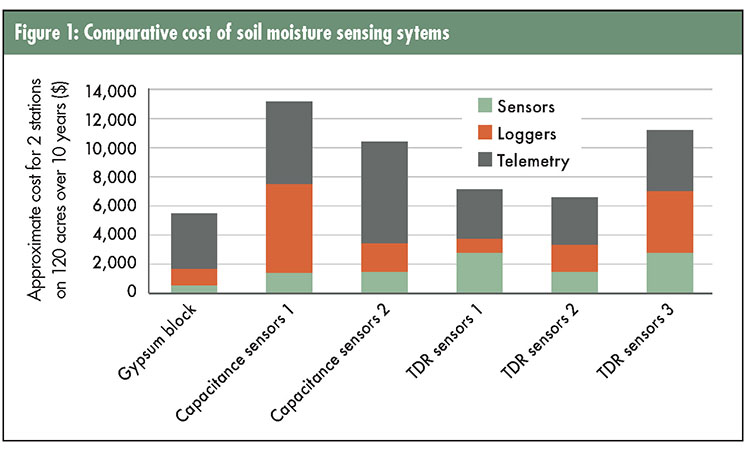

Compare costs After deciding measurements of interest and the components and number of systems needed, the final step is to consider the cost of various options. In addition to equipment costs, be sure to include the cost to install (labor and equipment), maintain (extract and reinstall sensors, replacements, and so forth), and access data for the life of the sensing station. To illustrate potential costs of various systems, we evaluated six sensing systems currently on the market (see graph, brand names withheld). In our scenario, we selected two stations for 120 acres (a typical center pivot). Each station had between roughly one and six sensors depending on the type to represent the soil profile, one logger, and telemetry where available. The cost for the 120 acres over a 10-year period ranged from $5,600 to $13,300. This did not include the highly variable installation or maintenance costs, which could almost double the costs in some cases. These equipment prices may seem steep, but when considering them on a per-acre basis, they calculated to $5 to $11 per acre — near the cost of most tillage operations.  Worth the investment? Based on our scenarios, growers would need to realize at least $5 per acre per year in savings to pay for soil moisture sensing. In current markets, that would require about 0.10 tons of additional alfalfa per acre per year or 0.5 tons of additional corn silage through improved irrigation. Unfortunately, few studies have documented the potential yield gains from soil moisture monitoring. Early results from a Utah State University study on 15 cuts of alfalfa at 10 farms in south central Utah during 2019 showed inconsistent and minimal yield gains when soil moisture monitoring was used compared to the grower’s conventional irrigation management. However, soil moisture monitoring did save water without reducing yield, suggesting it is a viable option for stretching limited water supplies. Soil moisture sensing can be a great tool for refining and improving irrigation management of forages. Utilizing the information provided here will help you determine which applications might be right for you. If the numbers are favorable and water supplies are tight, start small with a few systems on a few fields to ensure the benefits outweigh the costs before expanding to the whole farm. This article appeared in the March 2020 issue of Hay & Forage Grower on pages 12 and 13. |