Sorting out snaplage |

| By John Goeser |

|

|

|

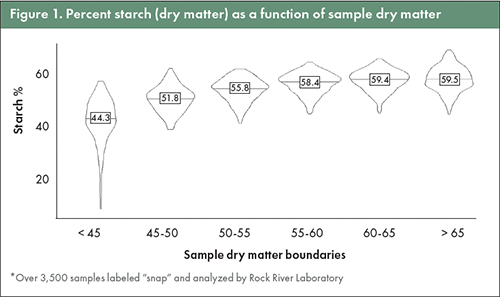

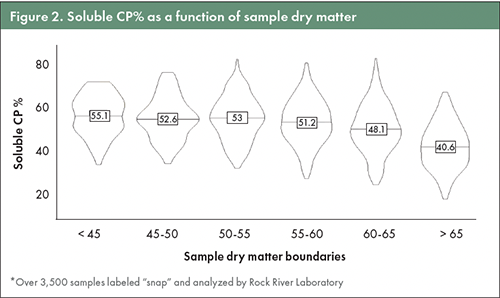

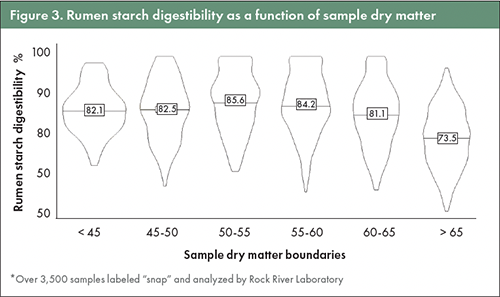

The author is the director of nutrition research and innovation with Rock River Lab Inc, and adjunct assistant professor, University of Wisconsin-Madison’s Dairy Science Department.  There are certain practices or technologies that seem to be heavily debated or discussed over the course of time. Kernel processing score and corn hybrid selection are two different topics that come to mind lately and have elicited questions and strong opinions. Snaplage is another, as it gains popularity among farmers but creates wide-ranging opinions among nutritionists. The beauty in snaplage lies in the farmer’s ability to run their self-propelled forage harvester, fitted with a grain head, after corn silage harvest. Other benefits include harvesting more yield than shelled corn, improving the fermentation potential relative to shelled corn, and bringing some additional fiber in the diet with lower forage diets. The drawbacks to snaplage are reduced energy density relative to shelled corn, the need to adequately ferment and process the grain for optimal performance, and correctly timing harvest to optimize starch yield and snaplage digestibility. This last drawback is often debated and is the focal point of this article because there is still uncertainty that exists within the industry. Focus on starch Timing harvest for corn silage, snaplage, or high-moisture corn is a balance between kernel maturity and crop moisture. For each of these feeds, the harvest timing and processing are extremely influential factors for starch content, digestibility, and feeding value. To be clear, good-feeding silage, snaplage, or high-moisture corn are driven by their starch component. Fiber digestibility is important with silage, but new corn silage feeds worse than well-fermented silage because starch digestibility improves with time in storage. As the corn plant approaches the R5 stage and the kernel is roughly half milkline, the starch content and whole-plant moisture are generally ideal for silage. However, with healthier plants, we’ve recognized advancing kernel maturity while the stover and whole-plant moisture may not be ideal yet. This situation appears to have played out in many cornfields during this past year, as Rock River Laboratory’s database is suggesting harder grain in silage and lower rumen starch digestibility for green-chopped corn. This observation relates to kernel maturity and grain hardness. On the other end of the spectrum, as corn grain passes black layer and dries to 20% moisture or less, the starch digestibility drops off dramatically due to limited or nonexistent fermentation potential. Homing in on snaplage, we aim to balance starch content, digestibility, and fermentation potential as the corn plant advances through R5 and closer to black layer. Leaning again on the Rock River Laboratory database, we can visualize the changes in snaplage quality as dry matter content increases in the feed and moisture drops. As the corn crop progresses past R5 and silage maturity, the ear continues to deposit starch in the grain as it matures. Figure 1 details how starch content in snaplage plateaus around 55% to 60% dry matter. At this point, the grain has likely reached black layer, and no more starch is deposited. So, there is no point to letting this feed dry further, recognizing we depend upon fermentation for feeding value.  A suitable proxy Understanding feeding value and its ties to rumen digestibility, we can transition to visualizing soluble crude protein (CP) and rumen starch digestibility. Prior to direct rumen starch digestibility measures, we recognized that soluble crude protein is an effective indicator for fermentation extent in the silo. The more effective the fermentation, the greater the soluble protein content. Figure 2 highlights how reductions in soluble protein begins around 55% dry matter, or 45% moisture. This image suggests that fermentation is likely limited when harvesting at 40% moisture or less. Figure 3 focuses on rumen starch digestibility. Rumen starch digestibility mirrors soluble CP and clearly depicts that below 35% to 40% moisture will correspond to less digestible starch. The optimal starch digestibility appears in the 40% to 50% moisture window.   Weaving the three figures and observations together, the optimal dry matter content for snaplage appears to be around 55% to 60%. At this point, the corn crop has achieved a high starch level along with near optimal fermentation potential and starch digestibility. Bear in mind that kernel processing and ensuring effective fermentation are also critical aspects with snaplage. Do not cut corners, especially during high grain price times. The corn crop may present the potential, but if kernel processing or fermentation are limited, then the feeding potential will not be fully realized. Think of this like having a flat tire on your 1,000 horsepower forage harvester. This article appeared in the November 2021 issue of Hay & Forage Grower on pages 22 and 23. Not a subscriber? Click to get the print magazine. |