Making hay the Western way |

| By Amber Friedrichsen, Managing Editor |

|

|

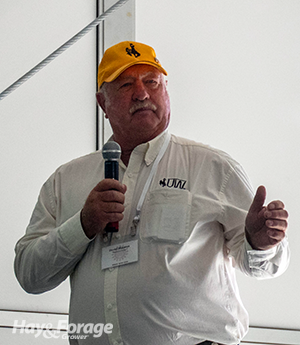

World Dairy Expo is known as the meeting place for the global dairy industry. It’s also an event for haymakers from across the country to come together and learn about the latest equipment, test out new technology, and find potential markets for their products within the dairy industry and beyond. David Hinman has been on both sides of this knowledge exchange as a regular participant in the World Forage Analysis Superbowl and speaker on the expo’s Dairy Forage Seminar Stage in Madison, Wis. Last week, Hinman shared his experience making award-winning hay in southeast Wyoming with the audience, starting when he moved from western Nebraska to Wheatland, Wyo., in 1984. Irrigation growing pains Hinman began renting a 400-acre farm on rocky ground with limited access to water. Even though crop prices were good at the time, the growing conditions posed some challenges to the young farmer. He explained how irrigation was — and still is — the cornerstone for crop production in the area, with a history spanning back to the late 1800s.  David Hinman In 1883, the Wyoming Development Company started tunneling through the 2,380-foot granite mountain that stood between the Wheatland Flats and the Laramie River. Rock that was blasted and removed from the mountain was used to create a conveyance system of canals that diverted river water toward local farmland. The problem was, once water was redirected from the river, there was no storage available. Over time, farmers also found that natural water flow slowed and eventually stopped when the river dried up early in the season. Even with canals in place, water supply was not consistent in an area that receives 7 to 10 inches of rain per year. This prompted the construction of three reservoirs that occurred over several years. By 1947, many other developments and agreements had laid the foundation for the Wheatland Irrigation District, which was the first irrigation district to receive water via trans-basin diversion in the state. Today, the Wheatland Irrigation District encompasses more than 120 miles of canals and 11 reservoirs that service over 54,000 acres of farmland for corn, dry beans, sugar beets, barley, and Hinman’s main enterprise: alfalfa. All about alfalfa Hinman currently grows about 1,000 acres of alfalfa, which are mostly all under pivot irrigation. He takes four cuttings from the majority of his stands with 28 to 32 days between harvests. Soil in the area tends to be alkaline with a pH hovering around 8. Rock picking is a regular practice to prepare seedbeds and ensure field operations go off without a hitch. Hinman stated that gophers and prairie dogs are the greatest pests in his hayfields, making mounds that interfere with mowing and swathing. The weather, however, tends to be the redeeming factor for some of these challenges. “The reason we can put up good hay is because we have really low humidity, warm days, and cool nights. We can get that hay dried out and it’s still green,” Hinman said. He noted hay is usually baled early in the morning or late at night. The decision ultimately depends on the amount of dew. “You can’t small bale dry hay if there is no dew on it — it’ll just be stems,” Hinman said. “When I go out to make big bales, I try to get 90 to 100 tons done early in the morning. Our baling windows are pretty tight — maybe 30 minutes.” Hinman seeds alfalfa at 22 to 24 pounds per acre. He admitted that he keeps stands in production longer than what is typically recommended, with some of his current stands boasting an age of 10 years or more. After three or four years of harvesting pure alfalfa, he typically interseeds orchardgrass in a stand to boost forage yields and prolong its persistence. Mixed alfalfa-grass stands are harvested and baled into small square bales before being packaged with a Bale Baron and sold to horse owners in the area. This hay also goes to Oklahoma, Texas, Arizona, and as far away as South Carolina. Hinman credited his wife, Teri, as the operator of the small square baler. On the other hand, he primarily makes large square bales of alfalfa and mixed hay for a rather niche market of goat dairies in eastern Iowa. Goats are the end goal Hinman has won the commercial hay category of the World Forage Analysis Superbowl at World Dairy Expo several times, and this year was no exception. The veteran haymaker took home the gold for his commercial hay sample, as well as the runner-up title for the grass hay category. He attributes his long-time participation in the contest to opening the door to his largest client. Over a decade ago, Hinman was contacted by an Amish farmer in Kalona, Iowa, who was interested in his winning contest entry. The farmer asked for a truckload of alfalfa hay, and after that initial shipment, Hinman’s sales took off in the Amish community. He now supplies approximately 50 truckloads of alfalfa and mixed grass to more than 30 goat dairies every year. Hinman works with one buyer who orders hay on behalf of all the dairies, serving as the middleman between Hardrock Farms and the goat farmers. The goat farmers prefer feeding animals pure alfalfa hay after goats kid in the spring to ensure animals receive high-energy forage at the start of lactation. Then, when goats dry off, the farmers tend to feed more mixed hay since animals’ nutrient requirements are lower. Even so, Hinman tests all of his hay and always aims for good-quality feed. “With good-quality hay, the milk quality maintains, but the minute that forage quality goes down, goats have a hard time bringing that milk quality back up,” he explained. His relationship with the goat farmers has strengthened over time, and so has both parties’ understanding of each other’s operations. Following World Dairy Expo, Hinman, Teri, and their grandson, Connor, made a quick trip to Iowa to pay a visit to their best customers in Kalona. The World Forage Analysis Superbowl may have shined a light on Hinman’s farm, but the success and connections he has today all started with a move West, steady irrigation, and the desire to make good hay.  Hinman, Teri, and Connor show off a fresh bale of alfalfa hay at World Dairy Expo brought all the way from Wheatland, Wyo. |