This item has been supplied by a forage marketer and has not been edited, verified or endorsed by Hay & Forage Grower.

Case IH is expanding AFS Soil Command™ agronomic control technology to its Tiger-Mate™ 255 field cultivator, single-fold True-Tandem™ disk harrows and vertical tillage tools, and the Ecolo‑Tiger® 875 disk ripper. Building on its existing seedbed sensing technology capabilities, AFS Soil Command will now help producers precisely coordinate control of their tillage equipment from the tractor cab. This technology uses reliable Advanced Farming Systems (AFS) components to optimize machine settings as field conditions change.

“AFS Soil Command helps producers overcome the challenges of properly setting their tillage tool to unlock more agronomic potential of their seedbed,” said Chris Lursen, Case IH tillage marketing manager. “Case IH tillage equipment already sets the stage for an ideal seedbed, and now producers can choose to take soil quality a step further. They can use AFS Soil Command to make agronomically correct adjustments from the seat of the tractor, ensuring the entire machine is properly set.”

The agronomic consequences of a misadjusted tillage tool

A smooth and consistent seedbed across the entire field requires less reaction by the planter, but often producers adjust the depth of their tillage tools without adjusting other machine functions. On an Ecolo‑Tiger 875, for example, shank depth and disk depth could become misaligned. This can lead to a less efficient, uneven finish. Automatically coordinating these settings with the main depth adjustment is critical to creating a high-efficiency seedbed.

“In many cases, operators may not be aware of a misadjusted tillage tool,” Lursen said. “On a True-Tandem disk harrow, fore/aft levelness and Crumbler pressure should be evaluated when the disk depth is changed, but this doesn’t always happen.”

Now, with AFS Soil Command, all tillage settings remain optimized when main depth is changed, so producers can be confident that their real-time adjustments are making improvements that will lead to an optimal seedbed.

Adjust settings to optimize each tillage pass

Rugged and reliable precision tools

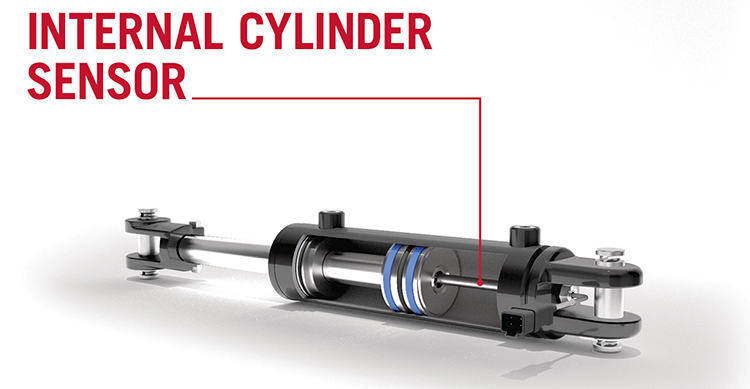

Internally mounted sensing technology is seamlessly integrated into Case IH hydraulic cylinders. These internal sensors are protected from damage in harsh conditions, matching the performance and ruggedness of Case IH tillage equipment for increased durability and less downtime.

“The beauty of AFS Soil Command is that any operator can seamlessly transition to this technology. Normal, everyday operation doesn’t change for the operator,” Lursen said. “For example, they will still use the tractor remote lever to lift and lower at every headland, just as with tillage tools without the control technology.”

AFS Soil Command agronomic control technology will be available for spring 2019 on the Tiger-Mate 255 field cultivator, single-fold True-Tandem disk harrows and vertical tillage tools, and the Ecolo-Tiger 875 disk ripper. This builds on existing AFS Soil Command seedbed sensing technology, offered on the Tiger-Mate 255 for spring 2019, helping growers optimize soil quality and improve yield potential.

For more information, visit your local Case IH dealer or www.caseih.com.