The author is the director of nutrition research and innovation with Rock River Lab Inc, and adjunct assistant professor, University of Wisconsin-Madison’s Dairy Science Department.

Coming upon nearly 100 years of silage science, researchers and farmers have long recognized that successful fermentation will preserve forage and grain long into the future.

Coming upon nearly 100 years of silage science, researchers and farmers have long recognized that successful fermentation will preserve forage and grain long into the future.

John Goeser

Preservation can be so effective that silage can maintain its nutritional value for decades. In fact, I’ve been witness to silage originally ensiled in 1988 that was later uncovered in a silo after a tough growing season dwindled the forage supply in a concrete silo to a level not touched in nearly 30 years. The 1988 silage was virtually indistinguishable from many 2018 silages.

Forages achieve stability because beneficial fermenting bacteria convert forage sugars into lactic and acetic acids when their growing environment reaches an anaerobic state. This process is moisture and temperature dependent. When successful, deteriorating spoilage yeast, mold, and bacteria are effectively eliminated or rendered dormant.

Much like leavening bread needs a warm and humid environment, fermenting bacteria need some heat to get the process going. This starting point is likely somewhere between 40°F and 50°F. As fermenting bacteria do their work, some heat is produced from the microbes digesting carbohydrates and creating fermentation acids, and the fermentation process continues until a pH of less than 4 to 4.5 is reached and the silage stabilizes.

In most years, an adequate temperature is not a concern as crops are harvested and stored during spring, summer, and well above freezing temperatures in fall. However, with challenging growing seasons where delayed planting or insufficient growing degree days push harvest into late fall, ambient temperatures may not be sufficient to kick-start the fermentation process in the silo. In these situations, forage may feed very differently than either your forage analysis or prior experience would suggest. There are several reasons for this.

More than a stabilizer

Forage stability is goal No. 1, but ensiling is also recognized to affect rumen and total tract starch digestibility. Ensiling breaks down a water repelling protein matrix that encapsulates the starch granules in corn grain. The protein in the grain is the same protein that lines paper cups, which are also made to repel water. Thus, if the grain isn’t soluble in water, the liquid phase rumen-digesting bacteria that degrade starch can’t gain access.

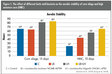

Ensiling and fermentation breaks down this protein matrix, freeing up the starch granules for digestion in the rumen and vastly improving feed quality. The resulting fermentation impact can equate to as much as a 20 percentage unit improvement in total digestible nutrients (TDN) for high-moisture corn or a 10-plus unit improvement in TDN for corn silage. Yet, if fermentation doesn’t proceed, then starch digestibility likely remains at the same meager state as it was when the crop was harvested.

Accurate laboratory feed analysis should capture this missing energy through rumen in situ starch digestion measures. If you suspect starch digestibility is limiting, also consider checking fecal starch content for your high-producing group(s).

Fecal starch is tightly related to total tract starch digestibility (TTSD). The goal for TTSD in dairy cattle is now less than 1% and feedlot diets are capable of resulting in less than 3% fecal starch. If starch digestibility is lacking, consider fine ground corn, sugar, or corn starch to help kick start the rumen.

Microbial overload

Beyond starch digestion, ensiling also changes the forage by practically decontaminating the feed of substantial levels of spoilage yeast, mold, and undesirable bacterial populations present in the fresh feed. This cleansing effect has proven critical in the U.S. as those in the Midwest and East have recognized higher microbial loads (yeast, mold, and possibly bacteria) over the past five years. Environmental conditions, tillage practices, and greater water activity (due to rainfall) are all likely contributing factors.

But bear in mind, if fermentation never has a chance to proceed, then these undesirable microorganisms may be present and carried through into the ration. During recent troubleshooting situations with both haylage and corn silage crops, several farms have recognized digestive upsets and performance challenges coinciding with the introduction of unfermented, wet feeds into the diets.

The working hypothesis here is that the feed is carrying a dormant microbial load that fermentation did not have a chance to decontaminate. Or worse yet, the unfermented crop served as a petri dish for undesirable microorganisms. When this forage is added to the diet, the microbial communities may wake up and thrive in the feedbunk, rumen, or both.

This impactful factor associated with frozen feed, beyond starch digestibility, isn’t assessed through routine feed analyses and requires more in-depth diagnostic efforts to grasp the magnitude. Consult with your nutritionist and veterinarian if feeding frozen forage or silage with limited to no fermentation.

Total mixed ration yeast and mold counts or an enterobacteria count may help identify a contaminating microbial load. If ration stability appears compromised or bacterial loads are excessive, isolate where the contamination is coming from. Either keep the feed from the diet or consider adding acid to the feed to decontaminate it prior to mixing in the ration. If unable to decontaminate, consider adding research-backed live yeast or bacterial probiotics to help the rumen negate the undesirable bugs.

There may be additional factors beyond those discussed here that also may be at play in your new crop forage. These include lower levels of crude protein and minerals, a higher mycotoxin load, or excessive soil (ash) contamination. Bring your agronomist, nutritionist, and veterinarian to the table for a discussion regarding these factors and potential impact on your farm.

This article appeared in the February 2020 issue of Hay & Forage Grower on page 23.

Not a subscriber? Click to get the print magazine.