The premises were optimistic, but final results of scientific tests carried out by the team coordinated by Prof. Luca Rapetti, head of the Department of Agricultural and Environmental Sciences at the University of Milan, exceed expectations: forage harvested with Ra-Rake, the new double-wheel rake, generates an average increase in ash content which is 66% lower than the one harvested with other types of machinery.

The energetic value of forage is also preserved by a higher order of magnitude, when compared to energy loss values observed in swaths collected by other types of machinery.

Let's now evaluate the meaning and impact of this encouraging data.

High levels of ash in forage are troublesome: external ashes (soil, stones, debris) do not provide any nutritional value but rather deteriorate its features.

In other words, too much "soil" in hay worsens its quality and reasonably increases the risk of pollution with spores and bacteria. Moreover, if the animal swallows too much ash, milk quality and quantity can be impacted. [1]

The raking phase normally causes an increase of ashes in forage, since the machine always collects some debris when operating. But here's what happens when using Ra-Rake.

The following table summarizes a few scientific data gathered by tests.

(The first column shows the data relating to Ra-Rake, the second - "other" - those relating to the average of the 3 other types of rakes tested in parallel.)

| | Type of rake | |

| Variation | Ra-Rake | Other |

| CEN (% SS) | 0,552 | 1,641 |

| GP (ml/200 mg SS) | -0,328 | -1,397 |

| ME (MJ/kg SS) | -0,046 | -0,194 |

| NEL (MJ/kg SS) | -0,033 | -0,137 |

| UFL (n/kg SS) | -0,004 | -0,019 |

( SS = Sostanza Secca / Dry matter; CEN = Ceneri / Ashes; GP = Gas Production; ME = Energia Metabolizzabile / metabolisable energy ; NEL = Energia Netta di Lattazione / Net Lactation Energy; UFL = Unità Foraggere Latte / Milk Forage Units)

This table averages results of about 300 samples taken in Italy and Switzerland, in order to assess comparative variations in chemical composition and energetic value of forage. During these tests, RA-Rake worked in parallel with rotary rakes and pick-up rakes (merger).

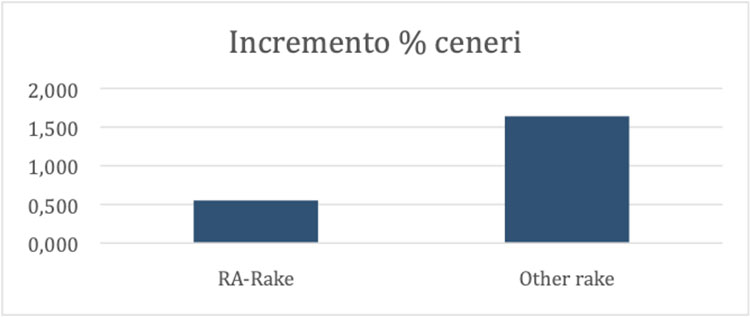

The first interesting data relates to the change in ash following raking operations. With Ra-Rake, tests revealed an ash increase of 0.552 (%SS), against an average measured increase caused by other machines of 1.641 (%SS); therefore, when compared to other rakes, RA-Rake generates an ash increase which is 66% lower (% difference between 1,641 and 0,552), as summarized in this chart.

In other words, the increase in ash content measured in forage harvested with Ra-Rake is about a third of the increase measured in forage collected with other types of machinery.

But this is not the only positive fact found by scientific tests conducted by the University of Milan: other values give us important information about the change in the energy properties of the forage after the passage of different rakes. The four values of Gas Production, Metabolisable Energy, Net Lactation Energy and Milk Forage Unit are absolutely in agreement and reveal interesting information.

The analysis of these data will be the subject of upcoming press releases. Stay tuned!

What is Ra-Rake?

For over a century Repossi Macchine Agricole has been designing and producing comb and rotary rakes; the latest addition to the range, RA-Rake is a revolutionary double-wheel rake, thanks to which in 2017 the company obtained a prestigious Horizon 2020 funding, launched by the European Union to promote and support innovation, research and technological development.

The innovation, ingenious but simple, allows farmers to exploit the benefits of wheel rakes without having to bear their negative consequences on forage: according to research by the University of Minnesota, the wheel rake is in fact the fastest and cheapest, but is also the one that collects more stones and soil. In fact, the single wheel, mechanically driven by the clutch with the ground, moves the hay, but in this way pollutes it with a large amount of ash.

Gabriele Repossi, the inventor of the new machine, had the idea of equipping it with two wheels of different diameters: the larger one does not touch the forage, but has the sole task of actioning the second smaller wheel, that moves the forage without polluting it with rocks and dirt.

Since the machine does not need complex and expensive mechanisms to move the smaller wheel, it benefits from reduced costs (both for purchase and maintenance) and allows it to operate at high speed, a peculiarity of single-wheel rakes.

Founded in 1898 and now in its fourth generation, the company looks to the future with innovative and patented solutions, including the RA-Rake double wheel rake, which in 2017 received Horizon 2020 funding from the European Commission.

[1] see: "Ealuation of the importance of digestibility of neutral detergent fibre from forage: effects on dry matter intake and milk yeld of dairy cows” - Oba and Allen - 1999.