The starting point to answer this question is often based on commodity grain market quotes at one or more points during the growing season. A fair price must be negotiated from the seller’s minimum and buyer’s maximum price perspectives. Buyers and sellers need to also consider local market conditions that might influence the final negotiated price. If the seller’s minimum price is greater than the buyer’s maximum, then it would be more economical to harvest the crop as grain rather than sell it as silage.

The seller has opportunities with marketing grain and opportunities for marketing or retaining the value of the stover in the form of soil nutrients and erosion control. The seller starts with the value of the standing corn minus grain harvest costs. The price is adjusted for the value of phosphorus and potassium harvested in the stover.

The prospective silage buyer starts with the price of standing corn in terms of quality and harvesting costs. The buyer usually assumes harvesting costs when corn is standing and adjusts the value of corn silage based on what it would cost to purchase corn and straw to replace the nutritional value of corn silage. Forage quality adjustments can be derived through milk marketing opportunities. Some corn, like brown midrib (BMR) hybrids, have more stover value than nonBMR hybrids.

Corn silage is often harvested after kernels are fully dented, with most acres harvested at about 50 percent kernel milk before grain is physiologically mature (black layer). Corn grain yield improves from 0 to 43 percent between full dent and black layer, with about 9 to 13 percent of the final grain yield determined after 50 percent kernel milk. A major factor in negotiating a silage price is predicting what the final grain yield would be in any given cornfield.

Grain equivalents

Our approach uses paired plots for collecting data to predict final grain yield using silage yield and quality measures. Half of the plot is harvested for silage yield and quality, while the other half is left standing for subsequent grain harvest using a combine. Experiments have been conducted at numerous locations over many years and experimental factors including hybrid, plant density, planting date, and row spacing, along with interactions.

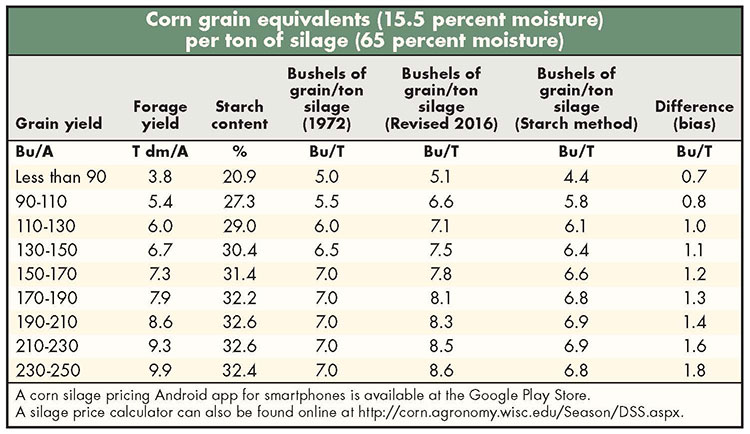

Grain equivalents (grain yield at 15.5 percent moisture divided by forage yield at 65 percent moisture) are often used in corn silage contracting. However, grain equivalents can be quite variable and change over time with the environment and management. In 1972, grain equivalents were estimated to be 5 to 7 grain bushels per silage ton for typical grain yield levels at that time. For modern hybrids used in our studies, average grain equivalents ranged from 5.1 to 8.6 bushels per ton, depending upon grain yield (see table). However, depending upon hybrid and environment, grain equivalents could be as low as 3.8 bushels per ton and as high as 10.5 bushels per ton.

In order to accurately use grain equivalents in contract negotiations, measurements need to be taken after the silage is harvested. Few growers are willing to leave “check strips” in the field. Weather, wildlife, hybrid standability, and ear droppage can influence grain yield measurements. A better approach might be to use a silage yield or quality estimates to predict final grain harvest yield.

Silage quality predictors

We have found forage yield to be a good predictor of final grain yield (R2= 0.70). The forage quality parameters neutral detergent fiber (NDF) and NDF digestibility were not good predictors of grain yield (R2 = 0.04 to 0.10, respectively).

Since the 1990s, an objective of the University of Wisconsin corn agronomy program has been to determine the relationship between silage starch content and final grain yield. Silage starch content is a common silage quality measurement routinely evaluated by forage testing laboratories.

Starch content has proven to be the best silage quality parameter for predicting grain yield (R2 = 0.29), but it is still not as reliable as silage yield. Assuming that starch was 70 percent of the grain, we used starch content and forage yield to back calculate grain equivalents (starch method in the table). This method consistently underestimated true grain yield equivalents. The difference (or bias) between these two methods was affected by the grain yield level. However, by using a forage yield measurement, a more accurate contract could be arrived at between grain producers and dairymen.

In conclusion, corn silage buyer and seller perspectives are different with each needing to develop a price from the seller’s (minimum to accept) and buyer’s (maximum to pay) perspectives. Cost of corn silage production has risen over time, so it is imperative to get a handle on these costs.

Grain equivalents in modern hybrids are greater than older hybrids. The relationship between forage and grain yield is quite variable. Starch content of corn forage can be used to predict grain yield; however, grain equivalents using starch content underestimate final grain yield and must be adjusted using a bias.

This article appeared in the August/September 2017 issue of Hay & Forage Grower on pages 10 an 11.

Not a subscriber? Click to get the print magazine