The concept of preserving forages as baled silage has become more popular throughout many regions of North America, and particularly in areas where weather norms make baling dry hay difficult and frustrating. Over the last several decades, baler design has been improved to accommodate the greater forage moisture and heavier weights of silage bales.

Another improvement in baler design has been the development of cutting mechanisms within the baler. These systems are primarily used to facilitate mixing of dry hay or baled silage into total mixed rations. However, it also has been suggested that cutting mechanisms may increase the amount of forage packaged into each bale, as well as potentially improving silage fermentation.

To address these questions, several experiments were conducted at the University of Wisconsin-Marshfield Agricultural Research Station using a New Holland Roll-Belt 450 round baler. The baler was configured with 15 equally spaced cutting knives across a 4-foot bale width, which roughly computes to a 3-inch theoretical length of cut. The system could be engaged or disengaged remotely from the tractor cab.

Small density improvement

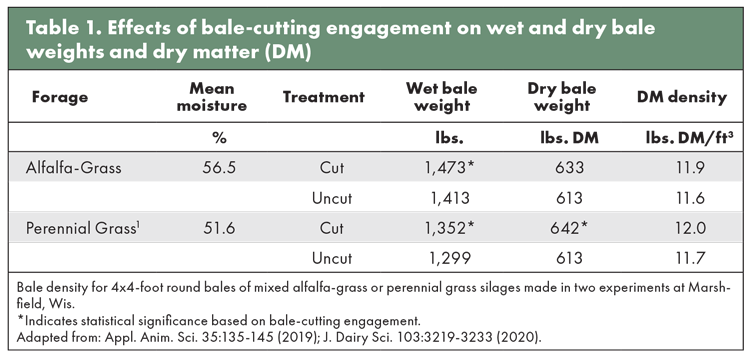

Responses to bale cutting obtained from two experiments are summarized in Table 1. In these studies, trends always favored heavier, denser bales following bale-cutting engagement, but the magnitude of these differences typically was only modest and not always statistically significant. It should be emphasized that many variables can affect bale density, such as windrow or swath density, bale moisture, forage species, initial or regrowth harvest of perennial grasses, baler ground speed, and other factors.

For studies conducted at Marshfield, a 5.5-mile per hour baler ground speed is normally maintained, except when experimental objectives require an adjustment. It should not be assumed that the responses summarized in Table 1 are reflective of all baling conditions. More definitive responses may be reported elsewhere.

Baleage is harder to ferment

Before discussing the potential effects of bale cutting on silage fermentation, it is worthwhile to compare the fermentation of precision-chopped and baled silages. This is difficult to illustrate because few research studies have compared the two silage types made from the same forage harvested at the same moisture concentration. The fermentation of baled silages typically is restricted. This occurs (in part) because baled silages are normally drier (45% to 55% moisture) and often are less dense than well-packed chopped silages. However, the chopping action itself also improves the availability of plant sugars to critical fermentation bacteria, further improving silage fermentation.

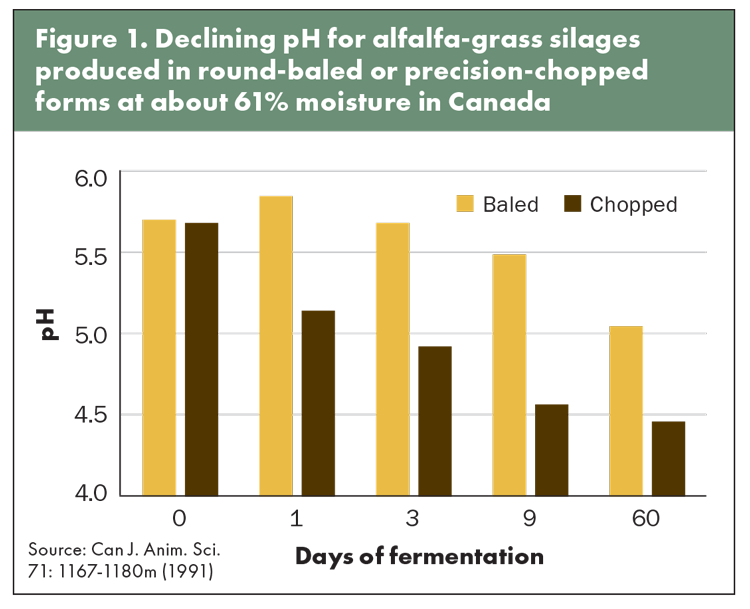

This concept is best illustrated by work conducted several decades ago in Canada (see Figure 1). In this example, alfalfa-grass forage was either precision-chopped or baled at about 61% moisture. Silage pH is presented at various time points during fermentation and clearly indicates a more rapid pH decline to a more acidic final endpoint for the chopped silages. This is the result of greater production of fermentation acids, and especially lactic acid, which is the strongest fermentation acid and most capable of lowering silage pH.

Based on this work, an obvious question can be asked: Do bale-cutting mechanisms create some of the same benefits as precision chopping with respect to improving silage fermentation? Potentially, this could be accomplished through two mechanisms. One possible mechanism is through any improvement in bale density, which purges air from the silage bale and makes the bale less porous to air. A second possible mechanism may occur through particle-size reduction that could improve the interaction of plant sugar substrates with critical fermentation bacteria that produce fermentation acids.

Modest improvement

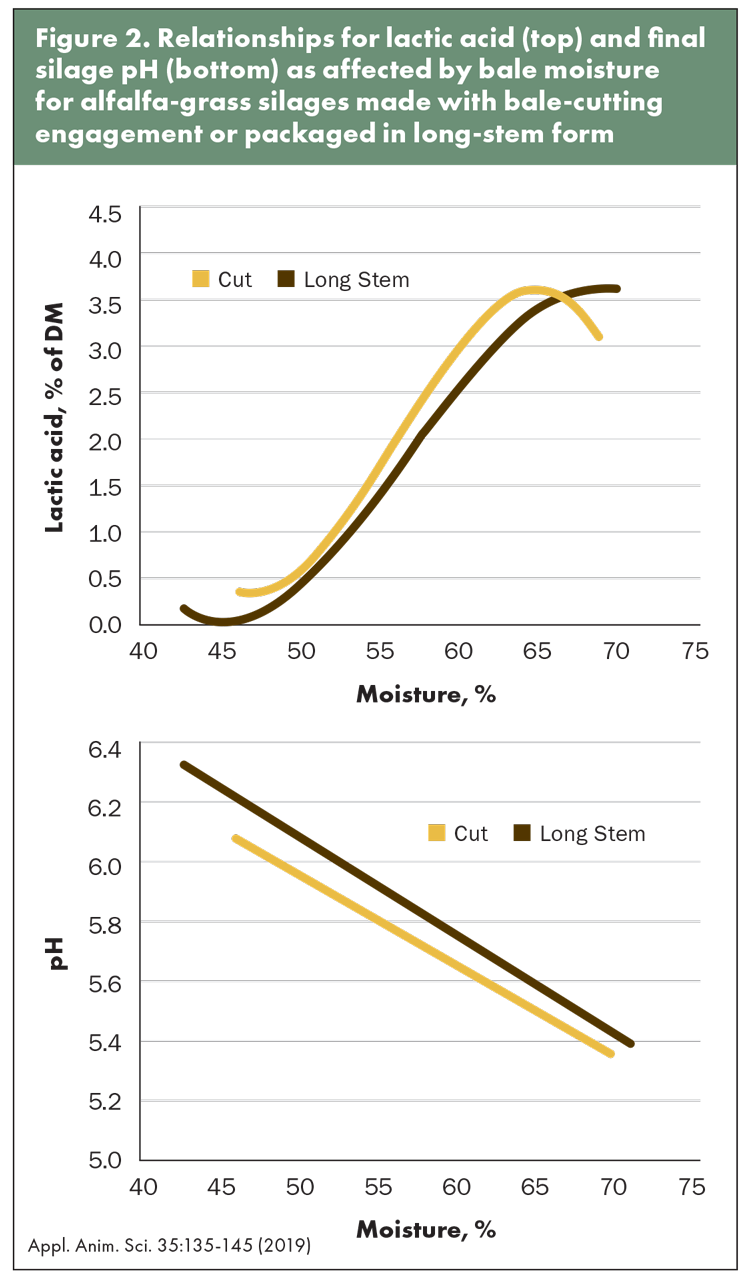

An experiment conducted in Marshfield, Wis., evaluated alfalfa-orchardgrass forages that were baled over a wide range of moisture concentrations. The bale-cutting mechanism was engaged or disengaged so that forages were either coarsely cut or left uncut in long-stem form, respectively. This experimental design allowed for assessment of silage-fermentation characteristics as they were affected by bale-cutting over a wide range of bale moistures.

Figure 2 summarizes these relationships for the production of lactic acid as well as final silage pH. Production of lactic acid was limited at low bale moistures but increased rapidly as bales entered the normal recommended moisture range for baled silages (45% to 55%). Regression relationships for both cut and long-stem silages were cubic in nature, meaning there were two inflections or bends in the regression line. These complex relationships were created by the limited production of lactic acid in dry silages as well as the formation of some undesirable fermentation products in wet silages, a process that often consumes lactic acid as a substrate.

Across the wide range of bale moistures evaluated, production of lactic acid was consistently greater, albeit modestly, with engagement of bale cutting. This resulted in a consistently lower (more acidic) final pH for cut silages. However, the magnitude of this effect was modest in scope, ranging from 0.10 to 0.15 pH units.

Moisture is more important

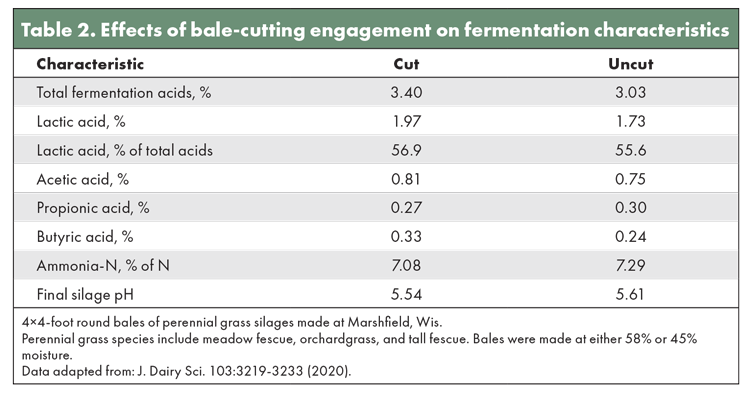

A second trial was conducted at Marshfield with three perennial cool-season grasses (orchardgrass, meadow fescue, and tall fescue) baled at two moisture concentrations (58% and 45%) and with or without bale-cutting engagement. Predictably, bale moisture had strong effects on silage fermentation. Concentrations of lactic acid were nearly 2.5 times greater in the wetter silages (2.62% versus 1.08%), and the final pH was sharply more acidic (pH was 5.33 versus 5.82).

However, the response to bale-cutting engagement can best be described as minimal (Table 2). The final pH of cut bales was 0.07 pH units lower or more acidic than long-stem bales, but this difference was not statistically relevant. Numerical advantages for cut silages were observed for total fermentation acids, lactic acid (%), lactic acid (% of total acids), and acetic acid, but only total fermentation acids approached a statistically relevant difference.

The presence of measurable concentrations of butyric acid must be emphasized. This fermentation response is indicative of some undesirable clostridial activity, particularly within the high-moisture bale group (0.52%) compared to the drier silages (0.06%). However, production of this undesirable fermentation acid was directly linked to bale moisture and was not affected by bale-cutting engagement.

Does bale-cutting engagement increase the amount of forage packed into each bale and/or improve silage fermentation? Based on the results of these studies, the answer to both questions would technically be yes, at least sometimes. However, the magnitude of improvements related to both questions were modest at best, and clear, statistically-based benefits did not occur consistently.

The studies reported here clearly do not cover all possible crops and/or baling conditions. Nevertheless, it would seem the primary justification for including bale-cutting capability in any baler purchase should remain a need to improve processing, often for ease of mixing into total mixed rations (TMR) or other blended feeds. Precut bales can often be directly added to the TMR without being processed in a tub grinder.

This article appeared in the August/September 2024 issue of Hay & Forage Grower on pages 26-28.

Not a subscriber?Click to get the print magazine.