Unless you’re putting your round bales on a scale, you’re probably guessing bale weight all wrong. The key word here is “guessing,” which spells trouble in terms of feed expenses and hay supplies.

Rob Kallenbach with the University of Missouri says guessing bale weight usually results in overestimating bale weight, sometimes by hundreds of pounds. This can be especially costly when buying hay by the bale instead of by the ton.

In addition to tacking on a significant surcharge, overestimating bale weight can contradict what you think you have stored in the barn. Factors like forage species, moisture level at baling, and baler settings can all impact bale weight. In fact, newer balers tend to pack tighter bales than older machines. Storage conditions and duration can further reduce bale weight as dry matter (DM) losses occur over time.

The only way to guarantee bale weights is to weigh them; however, most farmers don’t have the resources to do so. And since many sellers don’t allow buyers to weigh bales before making a sale, good estimation skills may be the best tool to ensure a good deal.

“It’s easy to misjudge bale weights, and those mistakes add up,” Kallenbach says. “Whether you’re buying hay or figuring out how much you’ve got stored for winter, a little math and common sense can go a long way toward making sure you don’t come up short.”

Quick equations

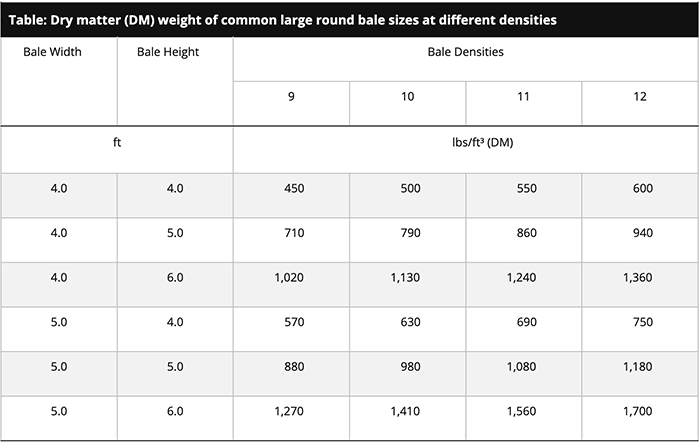

To more accurately estimate bale weight, figure out bale density and volume. The following are observational benchmarks that can help determine round bale density developed by Dennis Hancock with the Dairy Forage Research Center in Madison, Wis.

- Loose bales that depress and don’t spring back are likely 9 pounds of DM per cubic foot or less.

- Bales that are firmer but still give way when pressed are likely around 10 pounds of DM per cubic foot.

- Bales that are solid, yet can be dented with a hay spike, are likely around 11 pounds of DM per cubic foot.

- If it’s difficult to pierce a densely packed bale with a hay spike, it’s likely 12 pounds of DM per cubic foot or more.

Once you have a ballpark of a bale’s density, calculate its cubic feet, or volume. Divide the diameter of the bale by two and square that number. For a 5-foot by 5-foot round bale, this would be 2.5 squared, or 6.25. Then, multiply this number by 3.14, and multiply the product by bale width. In this example, bale volume would be roughly 98 cubic feet.

Use the bale density benchmarks and the calculated bale volume to determine bale weight. Based on this method, if a 5-foot by 5-foot round bale doesn’t spring back when pressed, it would contain roughly 880 pounds of dry feed. On the other hand, a densely packed round bale of the same size that cannot be pierced by a hay spike would weigh approximately 1,200 pounds.

Overall, Stacey Hamilton warns farmers of falling victim to what he calls “neighbor talk.” The University of Missouri Extension animal scientist sees this transpire when one producer pegs their bales at a certain weight, so the next producer assumes their bales must be the same. “That’s a risky way to do business,” Hamilton says.