Photos by: YSU Athletics & Wasuka Farms

Photos by: YSU Athletics & Wasuka FarmsLife experiences range from mundane to energizing. Custom forage harvester Keith Snoddy hasn’t had much of the former, logging many hours behind a chopper, a center, and on an oil rig.

The 67-year-old Shreve, Ohio, farmer grew up on a registered Holstein dairy operation that his grandfather purchased and his father eventually took over. “I hated milking cows, so I got more into the machinery end of things,” Snoddy recalled while sitting in his office chair during a visit from Hay & Forage Grower last summer. “After high school, I went off to Youngstown State University and got a business degree, not knowing if I’d ever come back to the farm.”

Snoddy did come back home to help his dad, but he didn’t stay long. He was enticed to start a job working in a Texas oil field. “That was when I figured out my place was on the farm,” Snoddy said. “After six months, I left Texas and came back to the farm in 1982.”

The back story

Snoddy’s return to the farm may seem like that of a lot of rural kids who work elsewhere and discover it’s with the cows and crops at home that’s where they want to be. But this farm kid had another pull on his life: He was an athlete, or more precisely, an exceptional athlete.

By his sophomore year in high school, Snoddy had become a varsity starter in football, basketball, and baseball at Triway High School near Wooster. He was the football team’s starting quarterback for three seasons and was All-Conference as a sophomore. He then led Triway to a conference title as a senior, gathering All-Conference, All-District, and All-State recognition.

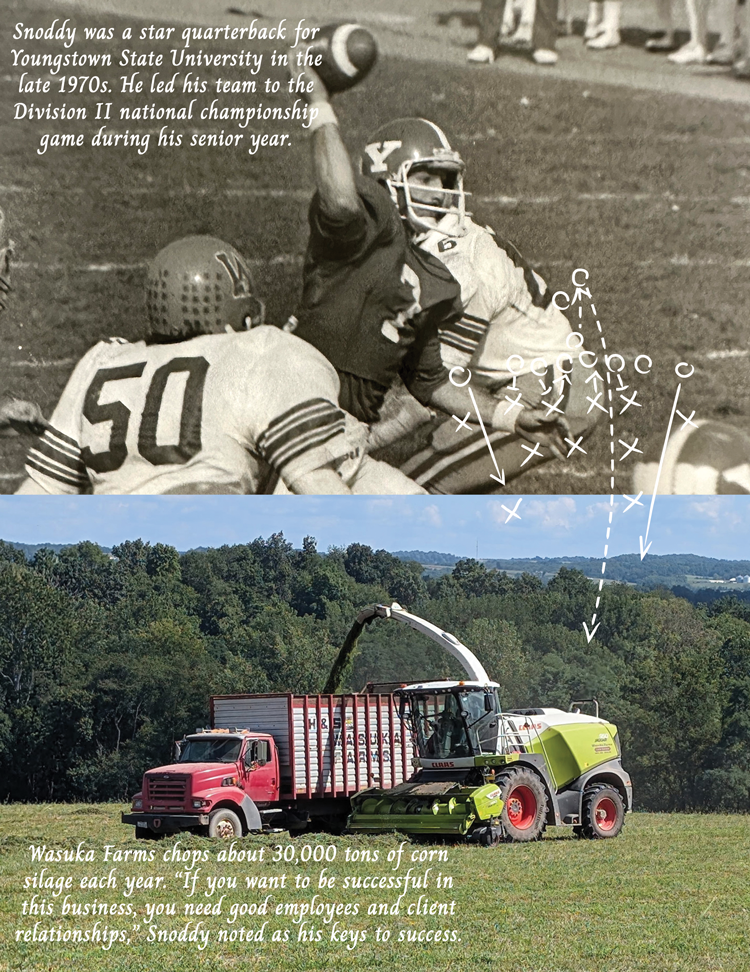

Snoddy’s prowess on the gridiron is what took him to Youngstown State University after high school. As their quarterback, Snoddy still ranks as one of the school’s all-time leaders in touchdown passes in a game (four, which he accomplished three times during his career), most touchdown passes in a season (19), and most touchdown passes in a career (40). As a senior, he was named an Honorable Mention Division II All-American.

“Athletics have been a big part of my life,” Snoddy asserted. “When I was at Youngstown, we played for a national championship my senior year. I had hoped to play beyond college, but pro teams weren’t looking for a 5-foot, 11-inch quarterback.”

When Snoddy returned home for good, the dairy cows were eventually sold. Once that happened, he was able to scratch his athletic itch again by coaching basketball during the winter. Starting with the school’s seventh grade team, he quickly worked through the ranks to head varsity coach at the high school he once starred for. Through his 11 years of varsity coach tenure, Snoddy had two teams make it to the state’s championship game. These days, Snoddy still assists the current coach. “Basketball always fit my schedule as a custom forage chopper,” he said. “It was a lot of fun, and all three of my daughters were cheerleaders for my teams during my years as the head coach.”

Getting a custom foothold

Most athletes develop over time, and the same can be said for a successful custom forage harvesting business. Snoddy’s venture into custom harvesting began in the late 1980s when he and his father decided to purchase a silage bagging machine for their dairy. “I bought the bagging machine, but then I also did custom bagging for other farmers,” Snoddy explained. “I got frustrated with how long it took some farms to chop, and I’d be sitting at the bagging machine for a half hour between loads. Finally, I asked them if I could just chop for them using our farm’s New Idea Uni-Harvester. Business started to pick up, so I upgraded to a John Deere 5830 chopper, eventually replacing that with a Claas machine.”

When the farm sold all the cows in the late 1990s, Snoddy transitioned strictly into custom harvesting. “This was done with my dad’s blessing. He always encouraged me, even though I hated milking cows,” Snoddy said. “His help and support were immeasurable when I got started.”

Kieth Snoddy knows his way around a forage harvester and a zone defense.

Kieth Snoddy knows his way around a forage harvester and a zone defense. Initially, the young forage-chopping entrepreneur planned to grow his own corn silage and then sell it to neighboring dairy farms. “I did that for a couple of years, but it just wasn’t a consistent income,” Snoddy confessed regarding his first business plan. “Then one of the area feed nutritionists approached me around 2000 about raising dairy heifers because we had a lot of unused facilities. We’ve continued to do that, and we now have about 700 head from a couple of different farms that we feed and care for. That has offered a more consistent income, and we use the crops from our farm to feed them,” he added.

Snoddy recalled that early into his foray as a custom harvester he would go just about anywhere to find work, but it was a lot of driving with equipment and trucks. “In the past 10 years, I’ve really backed off on the traveling and started doing most of my work for one nearby dairy that has several thousand cows and does 20,000 tons of corn silage per year,” he said. “It’s much easier this way.”

Currently, Snoddy chops about 30,000 tons of corn each year and does all four cuttings of hay on about 650 acres along with some acres where they just do the first cutting. Those totals include his own farm, which is tabbed Wasuka Farms and encompasses 350 owned and 150 rented acres. In addition to corn chopping, he also offers mowing and merging services for hay and currently co-owns a triple mower with flail conditioners.

Snoddy has six of his own trucks. He buys older Mack straight trucks with 20-foot boxes that self-unload. These work perfectly for the bagger, which is still used on the home farm and for some of his clients. Snoddy runs one 950 Claas chopper with a Scherer processor. For most of his years in the business, Snoddy would run a new chopper for three years and then trade it in for a new one. “I never felt comfortable with an old machine because I was chopping for a dozen farms,” he noted. “Major breakdowns weren’t an option.”

Snoddy has always been a bit of an innovator. Once, he went to a power show and saw a small camera and screen being sold and used on combines to view grain hopper unloading. He decided he could do the same thing on his chopper to monitor truck loading. These days, of course, most choppers come with this option.

Build relationships

Snoddy cites two key elements to a successful custom harvesting business. The first is to hire and keep good employees. He has two full-time employees, one of which has been with him for 35 years. During harvest, there is a call list of part-time workers, many of whom are retired from farming or other jobs. During the winter, Snoddy keeps his two full-time employees busy in the shop. “We do a lot of the machinery maintenance and repair work for the large dairy we chop for beyond just our own work,” he said.

“I’ve loved the custom harvest business, even if it is stressful,” Snoddy admitted. “I was put in a leadership position early in my life as a quarterback and a pitcher, so to lead a custom harvesting crew came as second nature. If you want to have good people working for you, you must treat them right. And to be successful in this business, you need good employees, and there’s just no way around that. If employees don’t look at the farm as you do as an owner, then there are going to be problems. Admittedly, it took me some years to learn how to manage employees. Too often, my temper got the best of me. Employees need to feel like they’re an integral part of the business. It’s up to me to make them feel that way,” he emphasized.

Snoddy’s second component for success in the custom harvesting business is a strong client relationship. “Your clients have to trust you,” he said emphatically. “This is a relationship-based business.”

Speaking of relationships, the Buckeye State farmer is quick to credit his wife, Cheryl, for enduring the kind of hours that a custom forage harvester keeps. “I couldn’t have made this work without her support and understanding,” Snoddy said. “She played a big role in raising our daughters when I couldn’t always be there.”

As for the future, Snoddy knows he’s on the tail end of his chopping career. “I’m 67 years old and don’t have any kids who will be taking over. I want to leave myself enough time to see the world. I’ve never been the guy who was going to die farming. I don’t just want to chase the rabbit; I want to catch it.” Down the road, it looks like there may be a position change from quarterback to receiver.

This article appeared in the January 2026 issue of Hay & Forage Grower on pages 6 to 8.

Not a subscriber? Click to get the print magazine.