Although summer weather is long gone, the effects of drought conditions linger on many livestock operations. This means purchasing feed will probably be a necessity on farms where forage supplies are low.

In a recent article from Kansas State University, Dale Blasi and Sandy Johnson note that feed and transportation prices are currently much higher following last year’s dry conditions. The beef specialists say the keys to keeping feed costs low this winter are taking inventory of forage, feeding animals wisely, and accounting for indirect expenses.

Supply and demand

First, take inventory of current forage supplies. Next, calculate the amount of forage that is needed to maintain production throughout the season. The difference is a good estimate to help determine how much additional feed to buy; however, there are several factors that can influence this number.

“Conducting a forage inventory necessitates the counting and estimating of the weights of all available baled and bulk forages on hand, the nutritional value of the forages, the class and weight of all livestock, and how the forage is fed,” the authors explain.

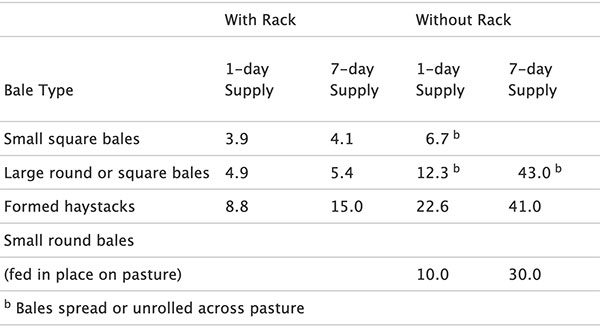

The way forage is fed impacts hay waste, which can either help or hinder forage supplies. Some factors that contribute to hay waste include trampling, leaf shatter, chemical and physical deterioration, and urine and/or feces contamination. Furthermore, the authors add the degree to which these factors impact forage loss depend on feeding method, time between feedings, weather conditions, and herd size.

For example, research from Kansas State University shows that unrolling large round bales of wheat or cane hay can result in 10% to 31% hay waste. On the other hand, research from the University of Missouri suggests feeding small square bales in a feeder can limit hay waste to roughly 4% (see table below).

Effect of hay feeding method on estimated loss (percent of hay offered)

The authors recommend feeding cattle smaller amounts of hay per feeding to minimize hay waste. Also, rotating feeding areas to well-drained locations of a field on a regular basis can reduce hay waste and damage to pastures.

Calculation tools

In addition to purchasing hay, producers may need to buy supplemental feed ingredients. Delivering supplemental energy or protein from the farmstead to the feeding area is an indirect transportation cost.

“Multiple trips per week may need to be made to pastures that are several miles away,” the authors state. “A worksheet called KSU-Cattle Supplementation Cost will account for the true cost differences in various supplementation strategies for mileage, equipment, and labor.”

The authors also suggest the Feed Cost Comparison from South Dakota State University is a helpful online tool to compare shipping cost per ton of two feeds based on forage quality. The Feed Energy Index spreadsheet from the Iowa Beef Center is another online tool that ranks forages according to an energy cost index, considering dry matter, energy levels, cost per ton, and estimated hay waste.

Amber Friedrichsen served as the 2021 and 2022 Hay & Forage Grower summer editorial intern. She currently attends Iowa State University where she is majoring in agricultural communications and agronomy.