The author is an associate professor and machinery systems and precision agriculture extension specialist with the University of Wisconsin-Madison.

When it’s time to harvest alfalfa for silage or hay, we are usually concerned about getting the crop cut at the right time, hitting weather windows for good drying conditions, and removing the crop from the field while maintaining the correct moisture and quality. How often do we give any thought to the machines we use in terms of tire pressures, ground pressure from machinery tires on plant regrowth, and machinery traffic patterns in the field during harvest?

Research at the University of Wisconsin-Madison suggests that these considerations are also important to alfalfa yields and stand persistence. Ensuring we minimize damage to alfalfa stands during harvest will protect yield over time, extend stand life, and boost profit margins.

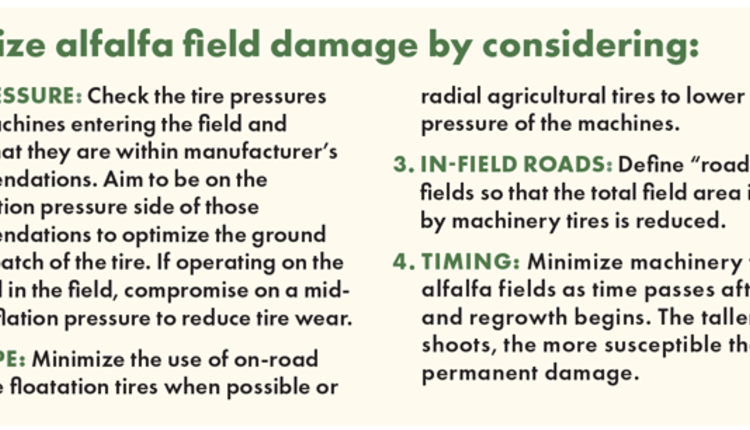

Ideally, when harvesting alfalfa, we would use the lightest machines possible. All of these machines would be fitted with radial agricultural tires capable of being operated at low tire pressures, and these machines would only be in the field when soil conditions were optimal for minimizing damage to alfalfa crowns without causing soil compaction. Unfortunately, farming doesn’t work that way. Often, an efficient harvest is required as opposed to operating in ideal weather and soil conditions.

Tires make a difference

Most machinery associated with alfalfa harvest use agricultural tires and are required for their specific operations. However, some of the greatest offenders to ground pressure applications are the machines used to transport the harvested crop from the field to the storage site. This is true for both alfalfa silage and hay production where trucks designed for on-road travel are used to haul the silage or hay and are driven in the field to collect the harvested crop.

In the case of silage harvest, our research showed that on-road trucks, specifically semi tractor-trailers, were the most efficient method for transporting silage from the field to the storage site. These machines have reasonable in-field speed, high carrying capacity, and high on-road speed that makes the transport of silage from the field to the storage site most efficient. In the same study, straight-framed trucks and tractor-towed carts were less efficient than semitrucks and trailers but were not statistically different from each other. This indicates that some level of transport and harvest efficiency can be maintained by utilizing machines equipped with agricultural tires compared to on-road tires.

Parker Williams at the University of Wisconsin-Madison surveyed multiple machines associated with alfalfa harvest and tabulated the average weight and associated ground pressure applied by these machines. This work revealed that machines involved in alfalfa harvest equipped with agricultural tires apply ground pressures ranging between 100 to 220 pounds per square inch (psi), while machines equipped with on-road tires apply ground pressures ranging between 520 to 820 psi. This increase in ground pressures applied by these on-road tires has great potential for lasting damage to the alfalfa crop. Whenever possible, try to utilize agricultural or floatation tires in alfalfa fields. These tires provide a wider and longer ground contact area that distributes the weight of the machine over that larger area, having less impact on the growing crop.

The pressure is on

Tire pressure also plays an important role in reducing damage to growing alfalfa plants. Williams calculated an average jump in ground pressure of 7.2 psi for every 1 psi of tire inflation pressure for agricultural tires. This rise is due to the ground contact patch of the tire being reduced as the inflation pressure increases.

Our research showed that vegetative index variations in regrowing alfalfa were impacted by machinery wheel traffic at various tire inflation pressures. Plots with machinery traffic applied by tires operated at lower inflation pressures showed more regrowth 10 days postcutting than those that had traffic applied with higher tire inflation pressures. Minimizing ground pressure by maintaining a lower tire inflation pressure will reduce damage to regrowing alfalfa and minimize soil compaction.

Damaged to dead

Alfalfa yield reduction is not the only concern when considering machinery traffic in alfalfa fields. In some instances, the wheel traffic damage can be severe enough to kill the entire plant. This has implications for the longevity of alfalfa stands and how many years the fields will be productive. The University of Minnesota’s Deborah Samac showed that wheel traffic reduced alfalfa yield between 12% and 17% when applied two days after each forage harvest. This study also showed that wheel traffic from machinery significantly reduced plant counts.

If wheel traffic is managed well in a field, the productivity of that field could be better maintained over time, allowing producers to leave fields in alfalfa longer. This would provide additional soil health benefits while maintaining desired feed production and forage quality levels.

In an ideal world, all of our machinery would have working widths that are multiples of each other so that the tires fall on the same lines within a field, but I can’t imagine a farmer or custom harvester selling or replacing a perfectly good machine just because the working width did not match with the other machines in the fleet. Since this is the case, true controlled traffic is costly and difficult to achieve in the purest sense. However, there are some steps that can be taken to minimize the area of the field impacted by machinery tires and minimize the damage caused by the machines. This is accomplished by controlling when machines are in the field.

Make it quick

Research conducted at the University of Wisconsin-Madison has shown that most of the damage caused to regrowing alfalfa plants when exposed to wheel traffic happens as more regrowth is present. When new shoots are present and growing, the wheel traffic has a much better probability of causing damage. This may not impact yield at the next harvest, but it does require the plant to “catch up” compared to plants that were not exposed to wheel traffic and possibly expend more resources to do so.

Limiting the number and type of machines in the field as more days past cutting occur is a good way to minimize damage. Also, having operators understand the importance of limiting the area impacted by wheel traffic is another good practice. If it is obvious that a machine has passed over a certain area, the subsequent machines can follow those wheel tracks to reduce the area impacted by tires. Defining in-field “roads” on headlands and when traveling to the chopper or collecting bales reduces the total area impacted by the tires. The plants within the “roads” will undoubtedly be damaged, but the total area impacted will be reduced.

There is a lot to consider when harvesting alfalfa for silage or hay. Giving some attention to the machinery used in the harvesting process can pay dividends over time in terms of alfalfa yield and persistence.

This article appeared in the July XL 2024 issue of Hay & Forage Grower on pages 24-25.

Not a subscriber? Click to get the print magazine.