I have been a forage agronomist for 30 years here at the University of Wisconsin during which time milk production of dairy cows has doubled, due largely to improved nutrition with high-quality forage. We have met the nutritional needs with better alfalfa production practices. The following are six major changes producers have made in the last 30 years to help capture high yields of high-quality forage.

Soil fertility management

Thirty years ago, less than half the recommended lime was applied to acid soils. Alfalfa needs a soil pH of at least 6.8 for optimum growth. Additionally, on all soils, the nutrient needs have increased with higher yields.

Soil testing and applying recommended phosphorus and potassium are common on well-managed fields. Tissue testing periodically is used to determine sulfur and trace mineral needs (both of which are occurring more commonly). Lastly, we now have the capability to determine yield continuously across the field when baling or chopping. Such will allow precision fertilizer and lime applications.

Improved alfalfa varieties/seed

Alfalfa breeders have tremendously improved alfalfa over the last 30 years. Alfalfa varieties have much more winterhardiness, which affects winter survival and yield for first cutting the next year. Breeders have broken the relationship between winterhardiness and fall dormancy so that winterhardy varieties with less fall dormancy are available. Less fall dormant types green up earlier in spring, recover quicker after harvest, and have increased late fall yield. The combination of more winterhardiness and less fall dormancy has also made a late fall cutting more feasible than in the past.

New alfalfa varieties also have more disease and insect resistance (particularly for the multiple races of aphanomyces, nematodes, and potato leafhopper). Genetic modification for increased fiber digestibility will have great impact on forage yield and quality. High-quality seed is also coated with two fungicides: Apron for protection from phytophthora and pythium and Stamina for protection from aphanomyces and rhizoctonia. Protection from these seedling diseases has greatly enhanced the ability to get a good stand.

Taking first cutting by quality

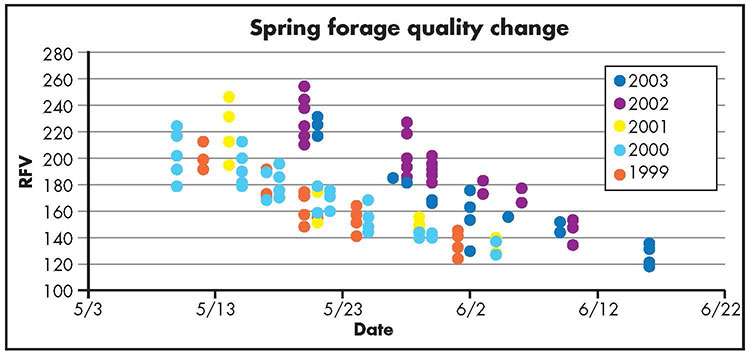

As shown in the graph, a given forage quality can vary annually for first cutting. Additionally, flowering does not relate well to forage quality on first cutting so cutting at the bud stage will result in variable quality from year to year. Many farmers used to take first cutting of alfalfa by a calendar date.

We would recommend cutting at a relative forage quality (RFV) of 180 or higher to end with a RFV 150 or better in the bale or bunker. Note in the graph that in 2002 and 2003 one could cut at June 1 to get RFV 180 forage, while in 1999 to 2001 one had to cut nearly three weeks earlier to get the same quality forage.

Research has shown that plant height (amount of stem) more closely relates to forage quality and forage quality sticks were developed to determine when to take first cutting. Thus, we have learned to take first cutting by height (28 inches for dairy, 32 for beef) or the bud stage, whichever comes first, to more consistently produce high-quality forage.

Better forage analysis

For many years we relied on two fiber determinations, acid detergent fiber (ADF) and neutral detergent fiber (NDF), to estimate forage quality. Research has shown that not all fiber is equal in digestibility or value to the animal. About 20 years ago, fiber digestibility became commercially and rapidly available through the use of NIRS (near infrared reflectance spectroscopy).

Relative forage quality (RFQ) as an index of energy intake was developed to more accurately assess the value of forage to animals using digestibility of fiber and other fractions. This has helped farmers better allocate hay to livestock and to buy and sell hay based on value to the animal. However, a 30- or 48-hour fiber digestibility is a snapshot and only indicates that this hay is better than that one; it does not necessarily predict how milk production will be affected. More recent tests, such as total tract NDF digestibility (TTNDFD), use rate of digestion and rate of passage, better estimating actual animal performance.

Wide swath drying

When conditioners became available for hay making 50 to 60 years ago, many farmers thought they could put hay immediately into a windrow instead of beginning the drying process in a wide swath. However, this was wrong. Research has shown that conditioning is for drying the stems and a wide swath for drying the leaves; the two processes are totally different. A wide swath is crucial to rapidly dry leaves to minimize respiratory loss.

This reduction of starch and sugar is both a dry matter and quality loss. Thus, the first benchmark in drying hay is how long it takes to dry off the first 15 percent moisture to minimize respiration and associated losses. With a wide swath, one can often harvest haylage the same day as cutting and it can be baled in three days or less. When hay is left on the field for five to seven days, yield is lost from reduced regrowth under the windrow and wheel traffic damage to regrowth. The longer drying time also delays irrigation for the next crop.

Wheel traffic damage

Fields must be driven over to be harvested, however wheel traffic causes damage reducing future yield. In fields sufficiently dry not to leave ruts during harvest, damage is caused primarily by breaking off the regrowth stems. The general principles are: 1) traffic sooner after cutting causes less damage and 2) a higher percentage of field covered with wheel traffic results in greater yield loss. The first point is why haylage fields harvested in one day yield more than hay fields harvested in three to seven days. It’s also why slow hay drying causes greater yield loss.

Regarding the second point, we have found that a bigger mower cutterbar reduced wheel traffic and boosted yield; this is also a reason we should merge windrows for harvesting. Less wheel traffic will result when using bale accumulators since traffic is reduced when removing bales from the field. Wheel traffic damage losses have likely increased as we have gone to quick recovery alfalfa varieties (less fall dormant) unless we have also accelerated haymaking speed.

Much has changed in the last 30 years to aid in production of high yields of high-quality forage. I expect that many changes will continue to occur to match the changes in the dairy industry. •

Editor’s note: Dan Undersander recently retired as the forage extension specialist at the University of Wisconsin. He plans to stay involved in the forage industry in a more limited capacity.

This article appeared in the November 2017 issue of Hay & Forage Grower on pages 18 and 19.

Not a subscriber? Click to get the print magazine.