The author is a forage agronomist with the William H. Miner Agricultural Research Institute in Chazy, N.Y.

Corn silage is a cornerstone of modern livestock nutrition, providing a highly nutritious and energy-dense feed option. Corn silage starch plays a critical role in meeting the energy requirements of livestock. Therefore, optimizing starch at harvest is essential for maximizing the nutritional value and performance of dairy and beef cattle.

Kernel processing is a pivotal component in unlocking the full potential of corn silage starch. Kernel processors break or crack the corn kernels at harvest, thereby enhancing starch accessibility during animal digestion. Proper kernel processing enables livestock to more efficiently utilize starch, leading to improved nutrient utilization and animal performance.

Unleashing energy potential

Most modern forage harvesters are equipped with specialized processors that crush kernels between two abrasive steel cylinders. These rollers rotate at different speeds, which enhances kernel size reduction. The roller gap can be changed to adjust the aggressiveness of the processing during harvest. The cost of a gap that is too wide is lost starch out the back of the cow. Too narrow a gap might cost you extra time and fuel at harvest. Current guidelines suggest that a gap setting of 1 to 3 millimeters (mm) is optimal for most conditions.

While kernel processing makes starch accessible by exposing more kernel surface area, the digestibility of corn silage starch is the metric that determines how quickly accessible starch is degraded by microbes. The worst scenario is to have corn silage with large pieces of kernel that are low in digestibility. There are many factors that can impact starch digestibility and understanding them is important to optimizing starch digestibility and harnessing the full energy potential of corn silage.

Grain maturity: Harvesting corn silage at the ideal grain maturity stage is crucial for maximizing starch digestibility. As corn kernels mature, starch content rises, but its digestibility declines. By harvesting corn silage at the 1/2 to 3/4 milkline, a balance is struck between starch content and digestibility. Harvesting too late impairs digestibility, but harvesting too early lowers yield and whole-plant digestibility due to a lower starch concentration.

Hybrid selection: Since kernel composition is largely genetic, the choice of corn hybrid significantly affects starch digestibility. More specifically, kernels that genetically express greater amounts of floury starch tend to be more digestible than kernels that produce the hard, vitreous starch characterized by flint corn. Advances in genetic selection have led to the development of hybrids with superior starch digestibility traits. Some of these hybrids even have a recessive trait that results in kernels that are completely composed of floury starch. The downside is that these hybrids tend to produce lower overall starch content as compared to conventional dent corn.

Moisture content and fermentation time: Plant moisture content at harvest is a critical factor influencing starch digestibility. Not only does it relate to kernel development, but adequate moisture is required for fermentation processes to occur that stabilize the silage for storage and feedout. These processes also have the effect of enhancing starch digestibility over time. Thus, silage that is overly dry or fed out within several months of harvest is more likely to suffer from poor starch digestibility. The optimal silage moisture content is around 65%.

The question of how to assess the quality of starch in silage has been highly debated over the years. The obvious gold standard is to feed the silage to cows and measure the actual starch utilization by the animal. While that works from a research standpoint, it isn’t too practical for the average farmer seeking to produce better feed.

Most farmers and nutritionists would have corn samples analyzed for 7-hour starch digestibility and perhaps kernel processing score. Measures of starch digestibility can be informative, but in vitro measures of starch often yield inconsistent results. Even the more precise assays available give an incomplete picture by failing to account for particle size. The current methods for determining the kernel processing score do provide a measure for starch particle size, but this measure doesn’t account for differences in kernel composition.

A new measure

A new metric for assessing the quality of silage starch was recently evaluated in a study at the Miner Institute in Chazy, N.Y. The assay has been termed “soluble starch” by the forage-testing lab that developed it, but it is really just a measure of the washout fraction of starch that easily moves out of the sample when water is added.

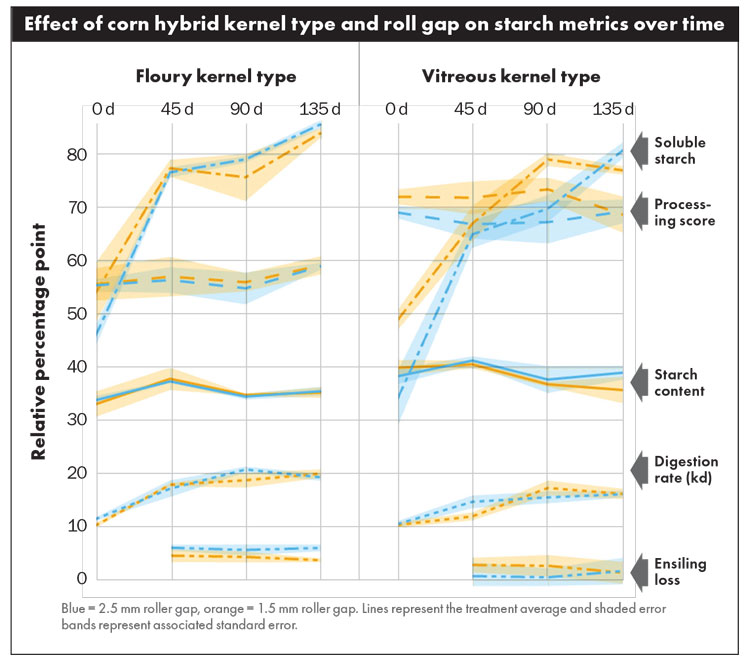

The exciting part about this new measure is that it appears to integrate both particle size and digestibility into a single number, providing an assessment that could correlate well with animal response. Our study results showed that soluble starch increased with fermentation time and was higher with a floury kernel type (Figure 1). This is the very same pattern that was observed with the starch digestion rate (Kd) measured in the study. Furthermore, a slight adjustment to the processor roller gap resulted in a measurable difference in soluble starch in unfermented samples.

Optimizing corn silage starch at harvest is a vital consideration for maximizing the energy potential and nutritional value of corn silage. Effective kernel processing, which is achieved with modern equipment and proper adjustment, plays a pivotal role in enhancing starch availability. Alongside kernel processing, other factors such as grain maturity, hybrid selection, moisture content, and length of fermentation significantly impact starch digestibility.

Optimizing these factors leads to improved energy utilization, feed efficiency, and performance for animals on corn silage diets. Utilize the best indicators available to make informed decisions about starch quality. Harnessing the power of corn silage starch sets the stage for enhanced profitability and sustainability.

This article appeared in the August/September 2023 issue of Hay & Forage Grower on pages 10-11.

Not a subscriber? Click to get the print magazine.