With the primary election season upon us, debates are common as voters attempt to formulate their candidate preferences. February is a cold period of the year across the U.S., yet election debates among candidates, friends, family, or colleagues can bring verbal heat to a room. Within farm shops, at a meeting, or in the local café, there’s another topic that often sparks opinion and debate — the proper moisture to harvest corn for silage.

Moisture content in corn silage doesn’t seem like an excitable topic, but its importance makes it debate worthy. Within agronomist, forage grower, harvester, and nutritionist circles, there is no clear consensus about the proper harvest moisture. There are seemingly two divergent opinions, much like many elections that boil down to one of two choices. The opposing views are marked by the preference to target corn silage harvest either from 68% down to 65% moisture or from 65% down to 62% moisture.

Here, we’ll discuss the case for each to arm you with better insights to make an informed management decision in the months or years to come. Prior to covering the two moisture categories, we need to understand how moisture content in corn silage has changed in relation to yield and quality over the past few years.

Advancing maturity and declining whole-plant chopped corn moisture concentration have historically correlated quite well. As kernel and whole-plant maturity advance, moisture concentration drops. This negative relationship has been driven by kernel maturity over time, where more starch is accumulated in the grain and moisture is driven out as the grain milkline advances.

At the same time of milkline progression, the fibrous stover and leaves tend to dry out as the plants “fire up” or die off. This latter change in plant physiology seems to have changed over the past few years, likely due to a number of contributing factors. I previously discussed this moisture and maturity disconnect in depth, noting that many hybrids now tend to stay greener and wetter for a longer period of time than what has historically occurred. Circling back to the debate between above or below 65% moisture, let’s discuss the case for each.

The drier camp

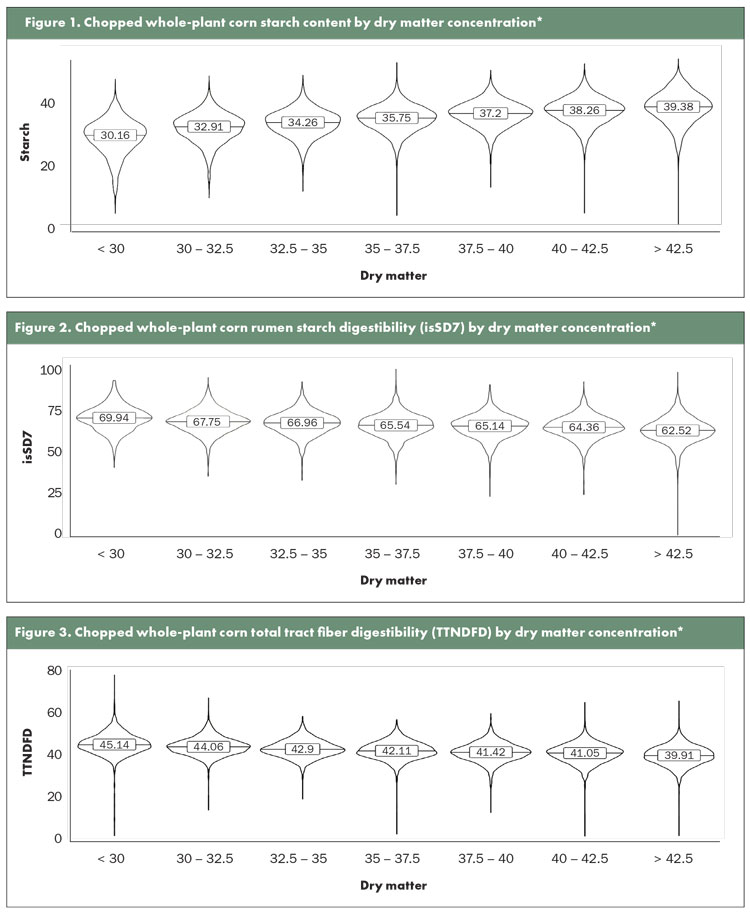

The farmers who target at or below 65% moisture are seeking a greater starch content and yield in their silage. The gains in starch, and potentially yield, with advancing kernel maturity through the silage season are not to be taken lightly, especially when the corn price is high. For example, Figure 1 details silage starch content as a percent of dry matter (DM) for two years of samples analyzed by Rock River Laboratory Inc. and bracketed into six categories spanning greater than 70% moisture, or 30% DM, to less than 57.5% moisture, or 42.5% DM.

Clearly, the drier the corn, the greater the starch content in silage. In theory, more starch equates to greater energy density per pound. The potential drawbacks to this silage is harder grain, drier stover with potentially less digestible fiber, and a harder crop to ferment — especially if plant disease settles in and plants die quicker than anticipated. Delaying harvest also puts you at some risk if the weather turns bad for harvesting just as the corn reaches 65% moisture.

The wetter camp

The case for at or greater than 65% moisture is driven primarily by the feeder’s desire for improved nutrient digestibility and secondarily by a need for adequate fermentation with lower storage and harvest risk. Both fiber and starch digestibility decline with advancing maturity and less moisture. Figure 2 highlights how rumen starch digestibility decreases with lower moisture for freshly chopped corn, and Figure 3 details how fiber digestibility also trends lower.

In some cases, the losses in nutrient digestibility can offset the energetic gains in starch when evaluating energy value per ton. Historically, wetter silage has also been less risky from a fermentation standpoint. Microbial inoculants or preservatives are recommended regardless of moisture, yet wetter silage has tended to ferment a bit better due to a couple factors.

Wetter silage will pack better and has a bit higher sugar content to drive a successful fermentation. The case for better fermentation assumes the silage is not so wet that it leaches, and this is no longer a safe assumption with today’s seed corn and agronomics. Over the past few years, more silage silos have been leaching for the same reasons that corn silage moisture and quality have disconnected. This is a stark concern for growers and feeders.

Ultimately, your primary goal with silage should be to harvest the greatest energy yield per acre relative to the crop production cost. Your secondary goal is to then preserve this silage efficiently and limit fermentation or storage losses. The arguments for at or above or at or below 65% moisture will affect both of these objectives, and there is no clear winner to the debate. It becomes a matter of preference.

This article appeared in the February 2024 issue of Hay & Forage Grower on pages 32-33.

Not a subscriber? Click to get the print magazine.