In the Field to Feedbunk column of the September 10, 2024, issue of Hoard’s Dairyman, Ev Thomas correctly pointed out that management is as important — if not more important — as forage variety in affecting forage quality. I’ve echoed similar comments when speaking about the interactions between seed genetics, management, and the growing environment.

Stepping out even further, I contend we can combine average seed genetics with excellent management to make above-average corn silage. Alternatively, if we take excellent seed genetics and couple that with substandard management, we’ll end up with suboptimal corn silage.

Soil fertility, agronomic practices, and harvest management — including kernel processing — are major control points under our influence. The energy value of corn silage is largely driven by the grain. In turn, processing corn grain is essential to ensure corn silage energy potential is fully utilized by high-performing dairy or beef cattle. We know that kernel processing score (KPS) is related to dairy or beef performance, and this drives interest in KPS.

Performance impacts

Beyond the interest in feed value, we continue to assess KPS because the topic resonates a bit differently than other feed analysis measures for a couple reasons. First, KPS is a physical measure characterizing the grain in silage particle size, and the physical nature of the analysis has different applications within the dairy and beef industries. The score equates to the percentage of starch passing through a 4.75-millimeter screen after the sample has been dried and sieved. To better grasp what this means, a 4.75-millimeter opening is roughly that of a 0.22 caliber projectile. Kernels need to be broken up into small pieces to fall through this sieve opening.

The second reason I believe KPS resonates so strongly is due to the wider ranging audience that is affected by the results. Typically, a feeder and their nutritionist will be interested in feed analysis results. However, the KPS is also influenced by the harvesting crew and their kernel processor.

Whether kernel processing is performed by a farm-owned harvester or a custom harvesting crew, this branch represents a third party that is involved. Hence, I find that KPS discussions continue to be livelier and capture greater interest than many of the other nutrition topics we’ve covered over the past decade. Now, let’s pivot and take a look at how we’ve advanced as dairy and beef forage producers over the past 10 years.

Elevated averages

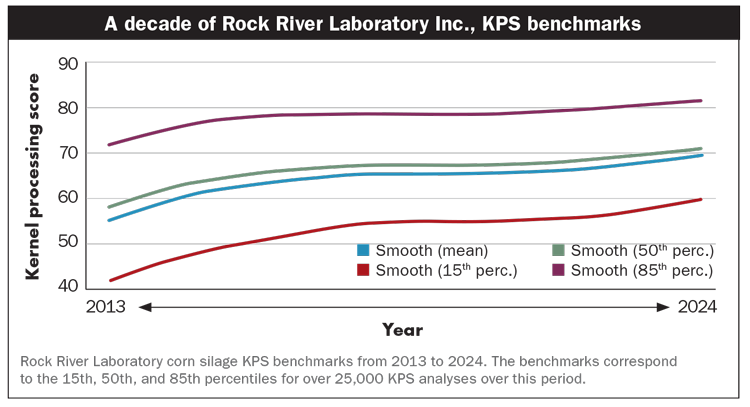

The western U.S. continues to slightly outpace Midwestern and Eastern growers in regard to KPS scores; however, as a whole, we’ve dramatically improved, as highlighted in the figure. This figure showcases annual KPS benchmarks from 2013 to 2024.

I tend to benchmark feed analysis results by breaking up data into the 15th, 50th, and 85th percentiles. For example, the 15th percentile corresponds to the lower 15% of the laboratory data. Then, I consider the 15th or the 85th percentile the goal, recognizing that the top 15% of results fall into this category either way.

For lignin or undigestible neutral detergent fiber (uNDF) 240, the bottom 15th percentile would be optimal, whereas for KPS, we want to be at the 85th percentile to be considered among the best. Over the past year, the best seems to continue to get better and I’m not sure where we’ll top out. This is excellent to see, especially as dairy and beef producer margins are historically thin and we continuously seek feed conversion efficiency gains.

Year after year, the entire KPS database shifts upward as well. The low end of the bell curve has risen quite a bit, with the bottom 15% now hovering around 60% KPS. This is also great to see, as a 60% KPS was the average a decade ago.

Drawing attention back to Thomas’ article in September, harvest management greatly influences the forage quality outcome. Building on those comments, we now have a decade of KPS measures showcasing just how far our corn silage management has evolved over the last 10 years. Keep up the great work and continue to push your management efforts forward for the next decade.

This article appeared in the November 2024 issue of Hay & Forage Grower on page 10.

Not a subscriber? Click to get the print magazine.