Haymaking takes multiple steps to achieve a high-quality product. Whether your goal is quality or quantity, the process remains the same: Hay must be dry enough to avoid spoilage but not so dry that excessive leaf loss occurs. Mowing, conditioning, raking, tedding, baling, and transporting — each step plays a critical role in preserving forage quality and yield. Even before harvest, tasks like fertilization and pest management add to the workload.

After all that effort, what comes next? We have to store it. Dry hay is a stable form of stored feed, capable of experiencing minimal storage losses — but only if it is managed properly. Without thoughtful storage, dry matter (DM) losses and mold growth can quickly undo the benefits of a well-executed harvest. Hay is often stored for six months or more between harvest and feeding.

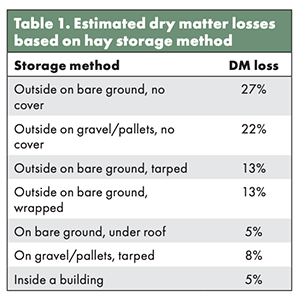

When it comes to round bale spoilage, it’s common to hear, “It’s just the outer 6 inches.” That perspective changes when you realize the outer 6 inches of a 5-foot diameter round bale make up over 30% of the bale’s total DM. Research from across the Midwest shows that DM losses after six months can range from as little as 2% to more than 50%, depending on location and storage method (Table 1).

It adds up

These findings clearly demonstrate that storing hay under a roof is the most effective way to reduce storage losses. Even if indoor storage isn’t feasible, simple changes — like storing bales on pallets or gravel — can significantly reduce DM loss. Adding a tarp or wrap can offer even more protection. In the “Basics of Haymaking” webinar series, Denise Schwab, an extension beef specialist with Iowa State University, highlights practical strategies producers can use to reduce DM losses and protect their investment as much as possible.

For hay valued at $100 per ton, every 1% reduction in DM loss translates to a $1 per ton of savings. That might not sound like much at first, but consider this: Switching from just storing bales on bare ground to storing them on bare ground with a tarp can reduce losses by 14%. On a 10-acre field yielding 5 tons per acre, that’s a $70 per acre savings — or $700 total. Simple storage improvements can pay for themselves quickly. Other strategies include using net wrap or B-wrap to help minimize water infiltration and reduce spoilage.

Major water issues

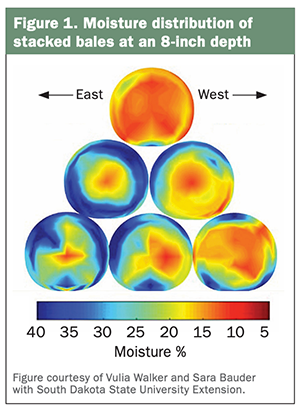

Dry hay acts like a sponge. Moisture moves from wetter areas to drier ones, meaning a dry bale at 15% to 20% moisture that is sitting on damp ground will naturally wick up moisture from below. This heightens the risk of mold and spoilage. Improper stacking can also create points where water pools, compounding the issue.

As shown in Figure 1, bale orientation and stacking matter, especially for round bales. Bales on the east side or bottom row often show the most spoilage due to limited airflow and water runoff from upper bales. When storing bales, points of contact are areas where water can pool and absorb in. Covering stacked bales outdoors can prevent top bales from funneling water down to lower ones and reduce exposure to rain and snow.

What are we losing?

So, what are we actually losing in storage? Typically, losses include nonstructural carbohydrates (easily accessible energy), digestible DM, and protein quality. Meanwhile, fiber concentrations and acid detergent insoluble protein tend to rise. In short, poorly stored hay becomes less digestible and less nutritious.

If outdoor storage is your only option, taking the following steps can significantly limit DM losses.

Select the right site. Store bales where they can be in full sunlight; avoid shaded areas like tree lines. Choose a well-drained location.

Avoid ground contact. Use gravel or pallets to prevent wicking.

Avoid stacking, unless bales are covered. If uncovered, tightly butt bales end-to-end in a single row.

Maintain row spacing. If storing bales in multiple rows, keep at least 3 feet between rows to promote airflow.

Align rows with a slope. If the site has a natural slope, run rows along it to encourage water runoff.

Use covers. Net wraps, plastic wraps, and tarps can all help reduce DM losses.

Another valuable resource for evaluating hay storage costs is the Ag Decision Maker Cost Calculator developed by Iowa State University. This tool allows producers to input specific variables, such as acres harvested, storage method, hay value, and the cost of infrastructure like hoop barns or other buildings to see how these factors affect overall costs and profit margins. Many inputs are customizable to fit your operation.

By accounting for expected losses based on your chosen storage method (for example, 27% for bare ground versus 5% under a roof), the calculator provides a clearer picture of the real cost of making and storing hay. For example, improving storage on a 10-acre field producing 5 tons per acre could save hundreds of dollars annually, reinforcing how critical storage decisions are to profitability.

Barns and hoop barns offer the greatest protection and cost-efficiency over time, but they aren’t always feasible. Base your decisions on how long hay needs to be stored, how much reserve is kept, and where feeding occurs.

This article appeared in the July 2025 issue of Hay & Forage Grower on page 10.

Not a subscriber? Click to get the print magazine.