On many farms, silage and haylage are the primary forms of forage harvest and preservation. Although less wilting time and lower dry matter losses in the field are often cited as being an advantage in silage and haylage systems, they are subject to huge dry matter losses once in storage, unless certain practices are adhered to.

Dry matter loss in a bunker silo, silage pile, or bag can’t be eliminated, but it can be held to a minimum. In times of high commodity and forage prices, savings during storage can amount to many thousands of dollars. Although minimizing dry matter loss is always important, there has perhaps never been a year before this one when saving dry matter in storage and during feedout will be so economically beneficial.

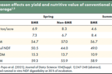

At the recent Silage for Beef Cattle Conference held in Ithaca, Neb., Becky Arnold noted that it’s important to focus on the four sources of dry matter losses. The custom harvest development manager for Lallemand Animal Nutrition listed these sources as: fermentation losses, leaching or seepage losses, surface spoilage losses, and feedout losses. In total, dry matter losses can range from 7% to 46%.

“Fermentation losses will always occur and often range from 2% to 6%,” Arnold explained. “To minimize fermentation losses, we must start by harvesting the crop at the correct moisture. Crops that are too wet can delay the ensiling process and lead to a clostridial fermentation. If the moisture is too low, packing and/or the ability to exclude oxygen become a problem. This may also increase nutrient losses at feedout.”

Arnold pointed out that available plant sugars in the crop are needed for the bacteria to convert them into lactic acid, which drives down the pH and preserves the feed. Less mature crops, crops that dry down quickly, and those that don’t suffer rain damage will generally have a higher plant sugar content.

“For lactic acid bacteria to do their job, they need an oxygen-free or anaerobic environment,” Arnold emphasized. “Spoilage organisms — the naughty bugs — will continue to proliferate if oxygen is present. Using a proven bacterial inoculant will help overwhelm the system and speed fermentation,” she added.

From the field

The silage specialist said that a standing crop hosts many types of microorganisms, some of which are good and some that are not so good from a fermentation and preservation perspective. All of these bugs get harvested.

“The bad organisms, such as yeasts and molds, will continue to multiply until the oxygen is gone and the pH drops with the production of lactic acid,” Arnold said. “This is why speed of fermentation is important. Once air and oxygen are reintroduced to the silage when the storage structure is opened, these bugs ‘wake up’ and continue to multiply. There will be more of them to do damage if a slow or inefficient fermentation occurred.”

You can help

In addition to harvesting at the right moisture and stage of maturity, Arnold asserted that there are several preharvest practices that can tip the odds of a good fermentation in your favor.

To speed dry down and help ensure uniform moisture loss, she recommended that forage be put into a wide swath. A higher cutting height will also help keep the windrow off the soil surface, allowing for better airflow under the crop.

Keeping soil out of the harvested forage also benefits the fermentation process. “Harvested” soil results in the silage having a high ash content, which dilutes the energy value, but it is also a source of detrimental organisms such as Clostridia. Silages with a high ash (soil) content are also more prone to butyric acid production.

During harvest, Arnold emphasized the importance of having someone assigned to monitor crop moisture, processing, and chop length. “When people assume someone else is doing it, that’s when we run into problems,” Arnold said. “A chop length that’s too long will make the crop more difficult to pack, results in sorting at the feedbunk, and contributes to much higher feedout losses,” she added.

“Ensuring an adequate silage pack density has a dramatic impact on dry matter nutrient recovery,” Arnold emphasized. “Our goal should be 15 to 16 pounds per square foot on a dry matter basis. This requires matching the weight and number of our pack tractors to the silage delivery rate in tons per hour and packing in 4- to 6-inch layers. At 8 inches, studies show we lose the ability to achieve our desired density.”

If there’s a problem keeping up on the pile, Arnold suggested to extend the length of the fill ramp to allow the pack tractors an opportunity to push greater distances without stopping.

Tire width and air pressure also influence packing effectiveness. Wider tires and lower pressure result in less surface compaction. “What we want in the crop field is just the opposite of what is needed on a silage pile,” Arnold said. “A poor packing density results in more air exposure, which slows the fermentation process, raises the final pH, and dramatically increases yeast counts.”

As we head into the 2022 harvest season, let’s recognize that our forage has never been more valuable. Forage “saved” during storage is every bit the equal of higher crop yields realized in the field.