A large majority of haymakers still utilize a forage conditioner on their mowers. These units are mostly out of sight, but they shouldn’t be out of mind.

Back in my university extension days, we started a statewide project to check the clearance on farm mower-conditioners. It was an eye-opening experience, as some of the units had a gap wide enough to run rebar through.

The technique we used to check gap settings was developed by Kevin Shinners, an agricultural engineer (now retired) with the University of Wisconsin.

The procedure is relatively straight forward and can be used to quickly determine the roll clearance on most roll-type mower-conditioners. Manufacturer guidelines for a functional roll conditioner are generally between 0.06 (1/16) to 0.09 (3/32) inches.

If the clearance is less than this range, excess leaf loss and roll wear occurs. If the clearance is significantly more than this range, then crop conditioning is less effective and drying rates will be slowed.

To safely measure the roll clearance, the first order of business is to lower the cutting platform and shut off the tractor or mower-conditioner engine. Next, disconnect the power takeoff (PTO) so that the rolls can be turned by hand.

You’ll need to obtain four items to perform the roll-clearance check:

• Aluminum foil

• Scotch tape

• A rod, dowel, or pipe that is 3/8-inch diameter

• A dial or digital caliper (available at most home improvement and hardware stores)

The procedure is as follows:

1. Cut three pieces of the aluminum foil to 18 inches in length. The foil strips should be at least 12 inches wide.

2. Using each strip individually, form three separate rolls by wrapping a foil strip around the rod, pipe, or dowel. Use a small piece of tape to keep the roll together. Slide the roll off the rod, taking care not to crush the foil roll.

3. Place one foil roll in the approximate center of the conditioning rolls and the remaining two foil rolls about 1 foot from each end of the conditioning rolls. The foils should be placed perpendicular to the roll’s longitudinal axis.

4. Make sure the cutting platform is fully lowered. This is the only safe way to make this measurement, plus, on some mower-conditioners, raising the platform also opens and separates the rolls, preventing an accurate measure of the minimum roll clearance.

5. Turn the rolls over by hand until the foil rolls come completely through the conditioner rolls.

6. The rolls will crush the foil rolls and the minimum roll clearance can be determined by using the caliper to measure the thickness of the foil roll. Take the measurement where the “crimp” or smallest clearance occurs. Make several measurements of the thickness along the length of each foil roll and determine an overall average.

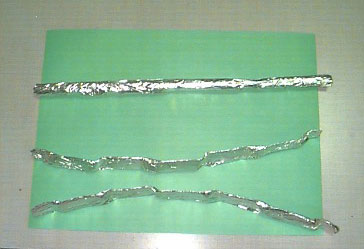

The photo below shows rolls before and after going through the conditioner.